OK, it may be premature to post something committing to building a guitar, but what the heck?

I've built lots of stuff, but never a guitar. Furniture, custom cars and motorcycles, knives, etc, etc. A little of this, and a little of that. I'm not expert at anything, I just like to tinker.

I'm also not much of a guitar player either, I just started learning about six months ago.

I've decided on building a Gibson-ish L-1 clone from Georgia Luthier plans. Over the weekend I started building tooling.

First, a go-bar press. I built it as a roll around cart with the idea I could store extra radius plates in the bottom. I'll probably add some dividers and shelves, and maybe doors to it once I have a better handle on where I'm going. Storing the fox bender would free up a little space in the shop.

The bender is nearly done. I need to add the springs and hold-downs, but it seems like it should work. I have three 150 watt light bulbs in it for heat. The form for the L1 is done. I lined the inside with thin sheetmetal and covered the top with thin stainless.

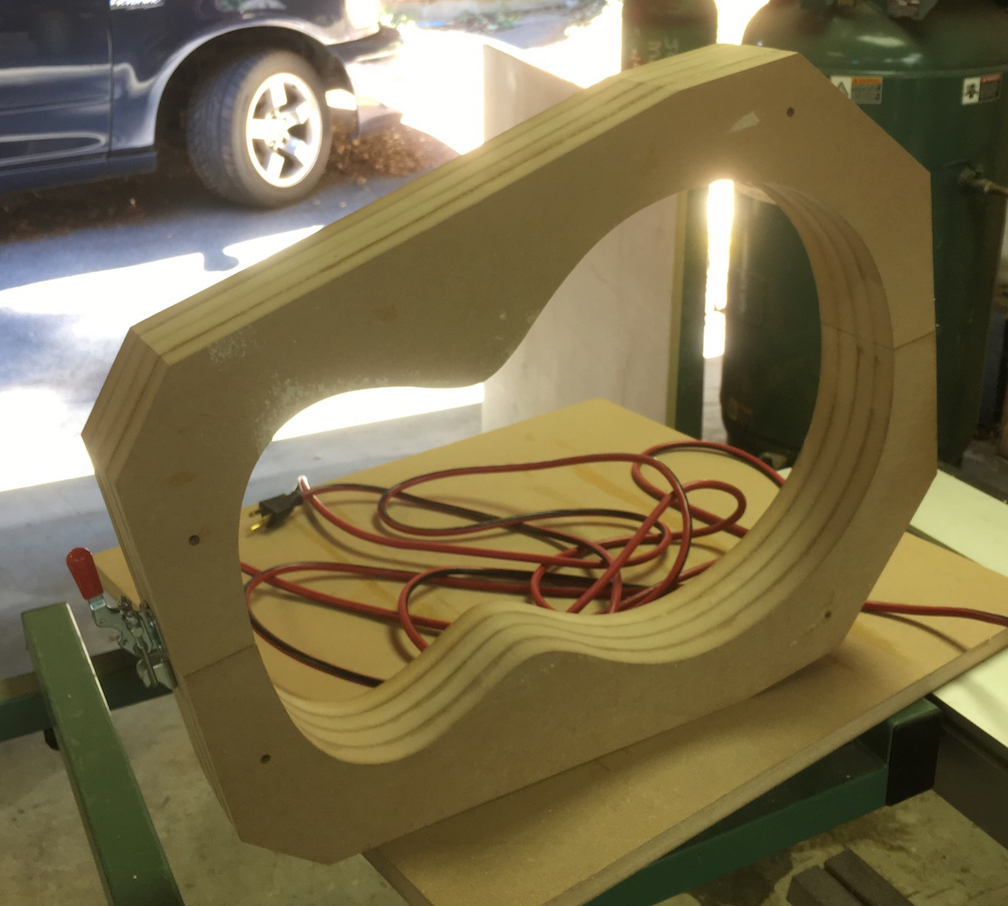

And finally the mold is done.

I ordered some materials from LMII and StewMac (kerfing, brace wood, spruce for the top, etc.) I have some Sapele that I'm planning to resaw for the sides and back. I'll probably make a bending pipe to pre-bend the waist as I'm concerned about that area. It will be interesting to see how this goes.