OK. Duders here be that brace shaving plane making thread me been promising...

And yes

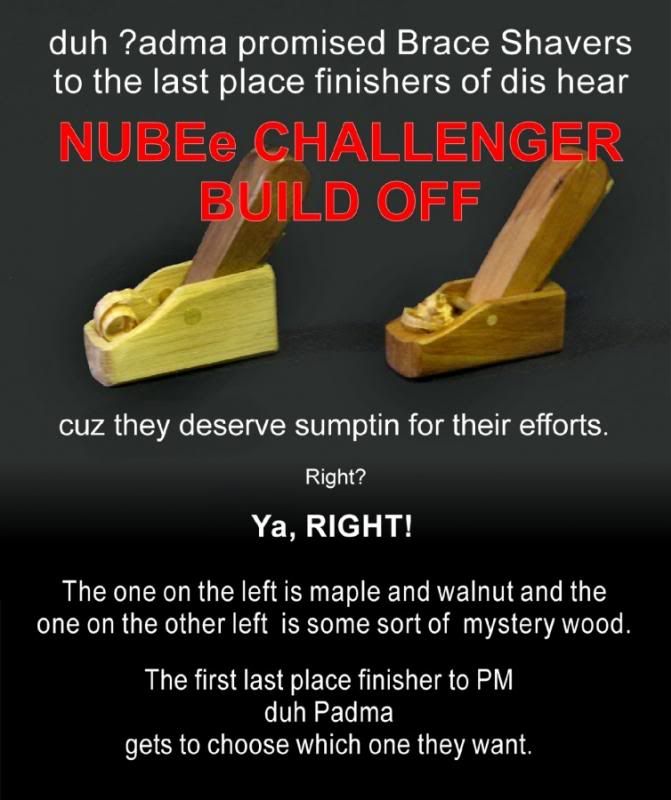

?adma gonna donate one of me

?adma gonna donate one of me Brace Shavers

as a

CONSOLATION PRIZE

to the last place builder in dis here

NUBEe CHALLENGER BUILD OFF THING

cuz they deserve sumptin for their efforts. Right? YA RIGHT!

These finger planes are a common design, found all over the net.

Stephen Boone makes a nice little one for brace shaving that he sells

for a real good price. Here is me quick and dirty version on a brace

shaver, a flat bottom and a curved bottom, all from an old Nicholson or

Black diamond file. Once you have made these 3, you will know what you

need your next ones to be like. Any wood will work, even a 2 x 4 but me

suggest a hard wood like maple, here me using birch cuz me haz a block

available, but

?adma, him have made them from all sorts of woods.

?adma, him have made them from all sorts of woods.

So

a chunk of wood, some 1/8 or slightly thicker brass rod and an old

Nicholson or Black Diamond bastard file. Me don't like the new ones as

they are much thinner steel Here be the layout....

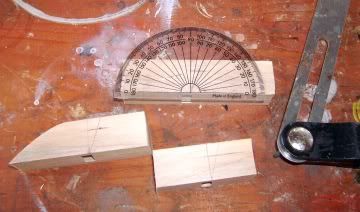

Cut a center piece slightly thicker than the file width. and two side

about 1/8 thick or thicker. The blade rests on the 45 to 50 degree angle

frog block. The other angle like most thinkgs, don't matter much. Cut out as in pic, glue

up and clean up the squeez out.

But

save the triangular cut outs for reinsertion to prevent blow out when

the holes for the rod are drilled. When dryed , cut out each plane.

Lay out of hole is about 1/3 from the top edge and about 70 to 80 degree

angle up from the bottom were the 45 degree face of the frog meets the

base.

drill hole the size of your rod (brass rod)...me uses 1/8 inch rod and a nail works too! Do you work?...me don'ts...no way ...me like play in shop...make stuffs and and and...never mind.

Band saw out the shapes you like.

Cut brass rod to length. Tap through and file or belt sand off. (don't got

any rod, use a nail) Grind the file into 3 or 4 pieces. Grind one two,

quench 3,4, 5. grind one two, quench 3,4,5,6. grind one two, quench

3,4,5,6,7 and so on. Be very careful not to over heat the file or you

loose the temper then what? Me no like loos temper...gives

?adma indigestion.

?adma indigestion.

The rabbit plane on the left will be covered in another post

Or...

if you want, the file can be annealed, then cut with a hack saw and

filed to final blade shape, but not to the final sharpen as a sharp edge

will tend to crack when hardened. Harden at about 1500 degrees or cherry

red , quenched in oil, . Then to bring it up to R60-62, temper in the

oven at 400 degrees for 25 min. and cool slowly. Now do your final

sharpening and hone them up. All thats a hassle so me just grind

the hard file nice and slow. She likes better that way, well so she tell me.

Cut a wedge shape piece and file, carve or belt sand into a cone. Round the

top. Drill a hole parallel to the blade and insert the cone as a push handle. Or if you got a

lathe ...make a nicer one.

To hold the blades in place, experiment with different wedge angles .

Shape two file blanks to a straight

edged iron and another into a curved iron. Grind the edges and a portion

of the back and front flat and smooth removing the cross cut teeth of

the file. Grind the other end square Sharpen and hone the two straight

edge irons. Do not sharpen the curved iron just yet. Then cut your wedges

to hold the irons. YOu might have to mess with wedge angles. Inset the wedge and iron and test the two brace shavers out. Tapping on the heal with a small hammer will retract the

iron, tapping on the toe will extend the blade it. Its an in and out sorta thing. Me usually just bang it down on the bench top to move the iron around. Ever wonder what moves you around?

Choose one for your curved bottom. First round off the bottom with a rocking back and for

forth on the belt sander, then a side to side and then combine the two

movements into a circular motion untill you gotts it convexed.

Once upon a time, long ago when the bottom is shaped to your liking, inset the rough curved blade blank, held in with a wedge and repeat the rocking on a belt sander with

an old belt save only for metal until the desired profile of the blade is

obtained ...then remove and sharpen the blade. They should look something like this when finished.

note were me ground a hollow for me finger to fit better.

Here are some other ones me has made.

Note the little hammer made from the

end of a truss rod and used for setting the wedge and tapping the blade

into the desired position. Any small hammer will do just fine...well almost any.

Note that some of the curved ones have a rather long toe on them, this really helps

in puttin the pedal to the metal when carving out arch toppers.

Plane making is kind of like eating potato chips...you can't make just one! Me gots a drawer full of them...some work better than others... but hey...a chunk of wood, a few old files, twist up a beer and smoke on. Nice no brainer way to spend an evening in communion with yer creative juices.

Summary...

grind up some old files, take a piece of 2 x 4 and make some plane

bodies. Once you have played with them for a bit...you will

know exactly what your needs in brace shavers or curved bottom planes

are then make them out of more fancier woods.

3 planes, 3 beers, 3 hours and me don't be work fast no way no how.

Push handles really help on curved bottom planes cuze you gotts a lotta

wood to remove in an archtop.

Also for archtops me suggest a

3/8s convexed,

1/2 in convexed ones, a few short and a few longer, the shorter ones without push handles,

a few 5/8s and 3/4 in ones with long toes and push handles.

Ya so grind up a few blades and wap out a whole bunch of bodies...find the bodies you like and then make the blades for them. Throw the rest out just like the swill in the bottom of the home brew.

Now regarding the last place in this here

NUBEe CHALLENGER BUILD OFF THING

whos it gonna be?

blessings

Padma

PadmaPs:

Now don't non of you dudes go be askin me about drawings with measurements...the file

used in these pics was a 1/2 Black Diamond...so scale your measurements

accordingly.