Charles,

I did the steps you mentioned w/the exception of gluing the plan to the plywood. I just traced it onto the wood.

Here are a few pictures of the mold.

These 2 photos show that is it fairly symmetrical.

This is the 2nd pic with both sides stacked.

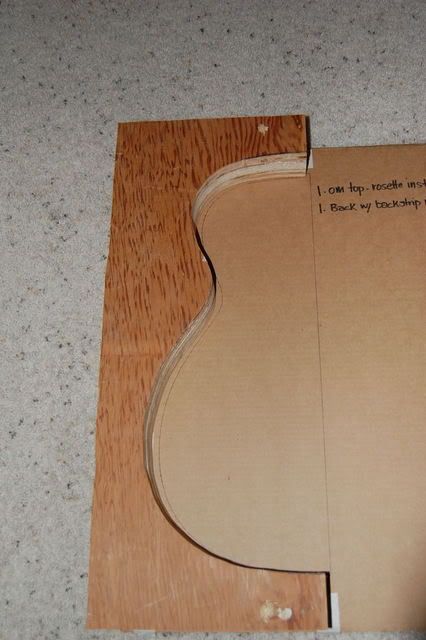

This shows the mold pulled away from the Martin supplied sketch a little to show that it is very close.

This is the type of waves that i am afraid of. You can see the white template against the mold and the dark area between shows the "wavy" area.