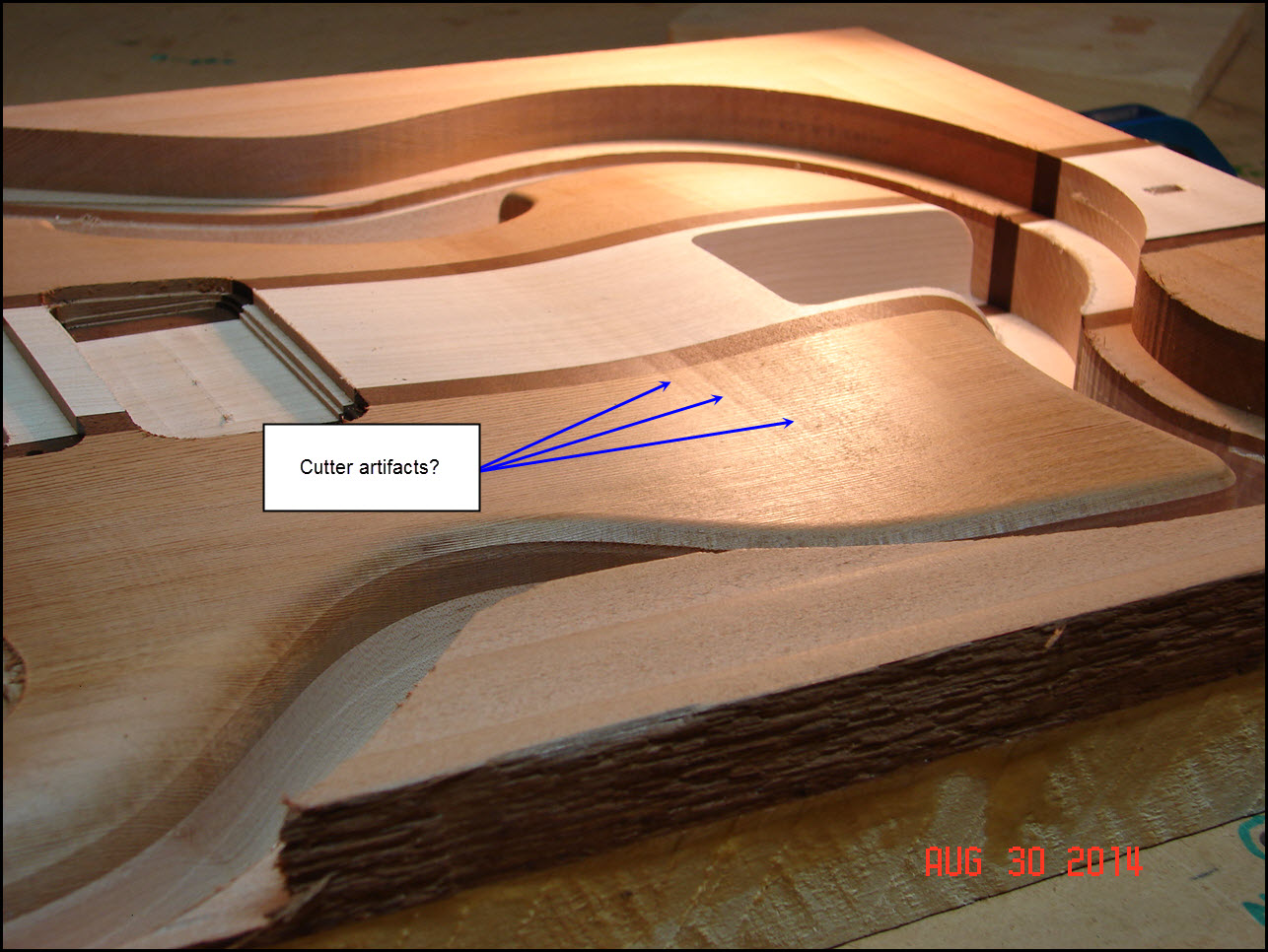

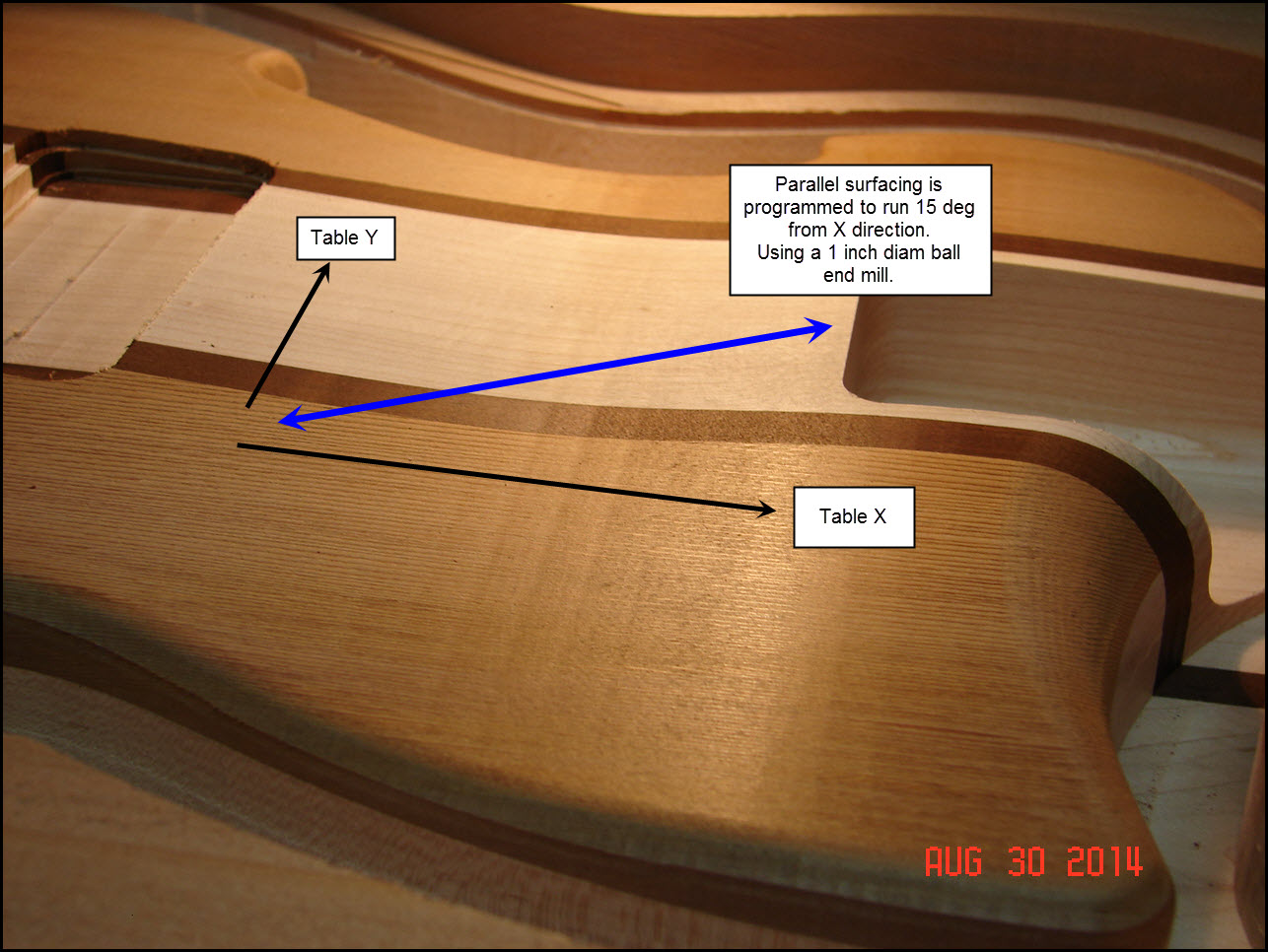

I've noticed this interesting artifact in a number of different pieces I've made on my CNC, and I'd like to get rid of it.

These are actually pretty subtle. I had to position the camera and the lighting to get them to show up in the photo. They sand-out, eventually.

Because the cutter is actually traversing back-and-forth at 15 degrees from the X-axis, I'm thinking it's some kind of strange artifact in the X-axis of my machine (ShopSabre 3636) - either the bearing ways, or the lead-screw. Or ??

Any and all theories, conjectures and thoughts on the issue greatly appreciated.

Thanks in advance,

Jeff