Hello,

I'm having problems with Visual Mill. I will import my Rhino 4 drawing and everything looks good except for surfaces. I'm getting a shift where the surface is not in the right place compared to the normal curves.

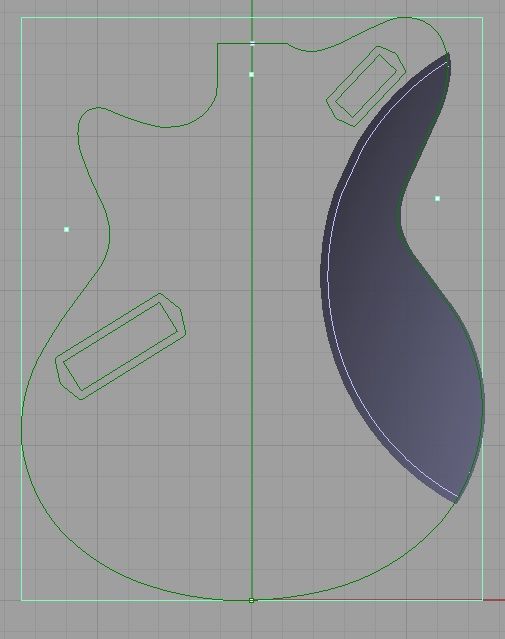

Check it out: here is my drawing in Rhino

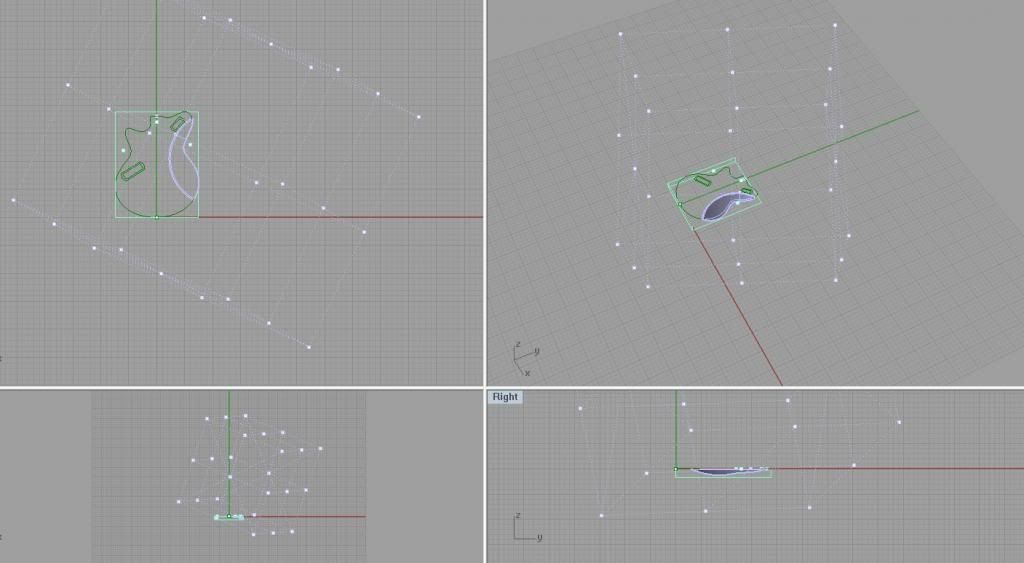

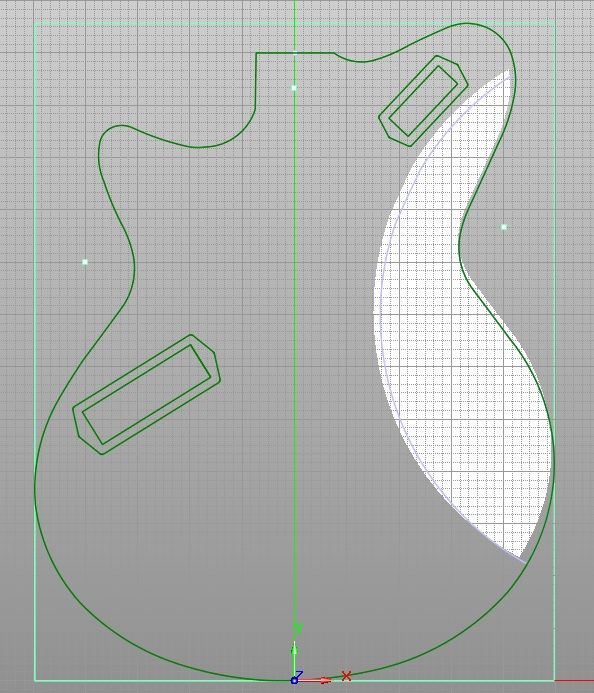

and here is what it looks like when imported into Visual Mill:

You can see how the tummy cut surface has moved up and over.

Does anyone know why this shift is happening?

As a workaround, I've been drawing a larger surface that is larger than my containment zone and it if shifts a little bit, it will still work-at least for this tummy cut.

Looking to fix this.

Thanks for any help!