Inspired by so many great threads in this section of the OLF, I thought I'd share some random pics from our shop. (Not my personal shop, but where my licensed production electrics are made.)

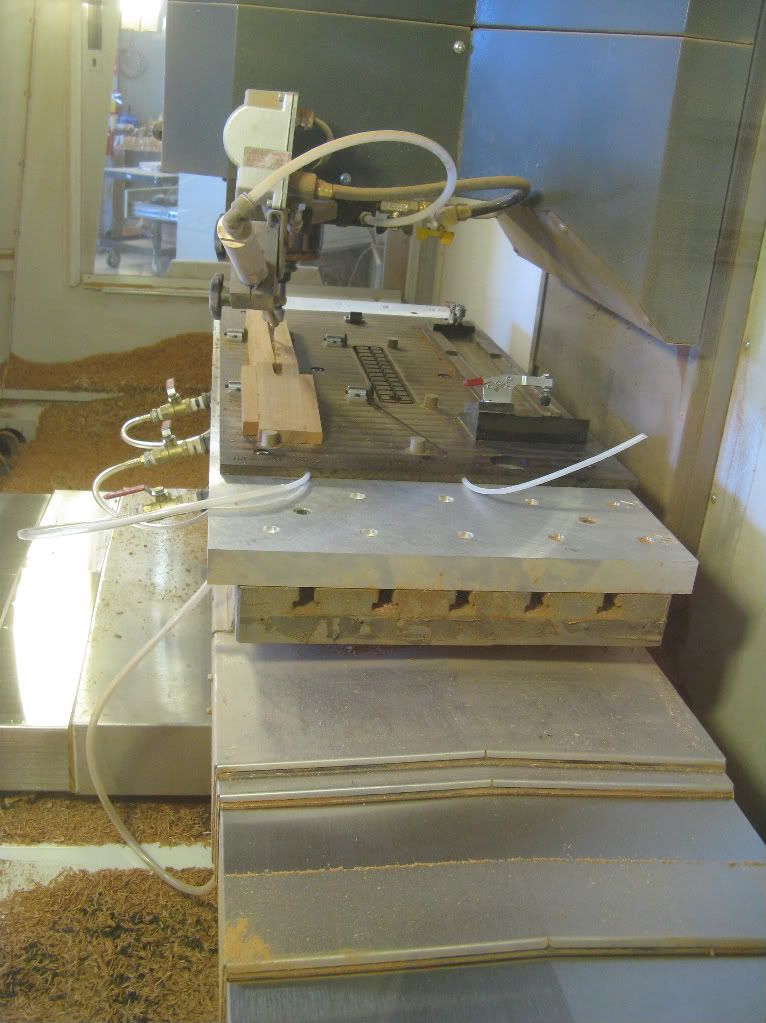

Here is some fret slotting being done on the HAAS

Making pickguard templates on the older K2 machine:

Cutting Tenons:

Here is a body holding fixture:

Here is a body holding fixture: Neck tooling:

Neck tooling: Neck holder, different position:

Neck holder, different position: Neck contours getting cut in it:

Neck contours getting cut in it:  This one does an initial fingerboard radius with a concave radiused cutter and adds preliminary relief in the process:

This one does an initial fingerboard radius with a concave radiused cutter and adds preliminary relief in the process:

Here's what we get from that:

Here are some phenolic blocks. We superglue shell blanks to these and cut out logos. When done, we put them in acetone to release. We do this for block inlays too, or any other shell shape we need:

And here is the recess getting cut:

Thanks for looking! cheers,

Thanks for looking! cheers,Saul

And a top:

And a top: