Zach,

The hold heet pots do tend to run a little hot. This is not nessarily a bad thing, in small doses and if you keep circulating your glue. The main thing is they are well made and consistent with temerature.

I mix a batch of glue and then cook it in the regular aluminum liner. After its dissolved, I put the rest of the glue in a container, let it cool and store it in the fridge. Cut it into chunks as needed through the day/week. This keeps the glue circulation up rarther than reaheating the glue constantly.

Leftovers in the jar/pot? Well, thats a judgment call depending on how long its been in the pot and what you need to glue next. Sometimes I save it for marquerterie or inlay. (yes, hide glue is perfect for shell and wood inlays!)

My glue sits around 145-150 in the jar. Around 150-155 in the aluminum pot / without the full water jacket. I really dont think that it is any problem.

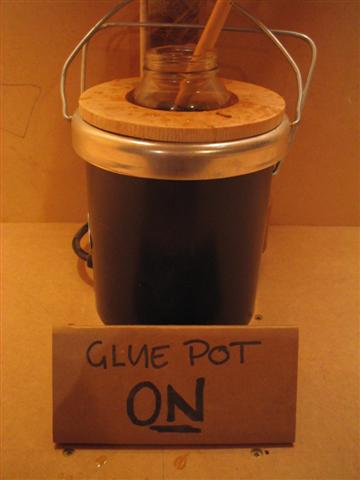

Mario! thanks for the tip! Im not terribly worried however, my big old sign works great. What I love about the hold heet pots is that they are made to last forever (a Lie Nielsen of glue pots), and dont burn out like them flimsy crock pots. And yes, before the sign I always used to leave the pot on all night! (which some people, I should note, do on purpose!)

|