Tony...any chance you could do a picture tutorial on how you make purflings...and how you would use the LN tools?

Now that would be Christmas for me!

TIA

| Official Luthiers Forum! http://mowrystrings.luthiersforum.com/forum/ |

|

| Interesting New Tools from LN http://mowrystrings.luthiersforum.com/forum/viewtopic.php?f=10102&t=15108 |

Page 1 of 2 |

| Author: | TonyFrancis [ Sun Dec 23, 2007 11:23 am ] |

| Post subject: | |

I have a slicing cutter and thicknesser in the mail. I make all my purflings by hand so having these makes it like christmas around the shop. Oh, wait!? About time, Lie Nielsen! |

|

| Author: | JJ Donohue [ Sun Dec 23, 2007 11:49 am ] |

| Post subject: | |

Tony...any chance you could do a picture tutorial on how you make purflings...and how you would use the LN tools? Now that would be Christmas for me!

TIA |

|

| Author: | TonyFrancis [ Sun Dec 23, 2007 4:21 pm ] |

| Post subject: | |

JJ, No problem, If you tell me how to post pictures! Making your own purflings is not hard at all, and gives one a much better array of woods to use. For me, I like holly and cocobola. J.French goes one step further and makes Marqueterie purflings.. LMI, eat your heart out!

|

|

| Author: | JJ Donohue [ Mon Dec 24, 2007 1:11 am ] |

| Post subject: | |

Thanks, Todd...you beat me to the pic posting instructions. Glad you're interested as well! Oh, boy Tony...can't wait to see this. I've been hoping to save more via the DIY method. Each year, I do more and buy less! |

|

| Author: | WaddyThomson [ Mon Dec 24, 2007 1:57 am ] |

| Post subject: | |

I'm looking forward to this, myself. I made some rope type stuff for my rosette, but it came out pretty crude. The devil is in the details. |

|

| Author: | TonyFrancis [ Tue Dec 25, 2007 1:59 pm ] |

| Post subject: | |

Thanks for the info guys. Making purfling and marqueterie this week (no time off this year!) so will make a post late next week. best, Tony

|

|

| Author: | TonyFrancis [ Tue Dec 25, 2007 2:58 pm ] |

| Post subject: | |

|

|

| Author: | TonyFrancis [ Tue Dec 25, 2007 2:59 pm ] |

| Post subject: | |

testing testing.... |

|

| Author: | TonyFrancis [ Tue Dec 25, 2007 3:10 pm ] |

| Post subject: | |

|

|

| Author: | TonyFrancis [ Tue Dec 25, 2007 3:23 pm ] |

| Post subject: | |

Todd, How did you say you re-size, again? |

|

| Author: | WaddyThomson [ Tue Dec 25, 2007 4:48 pm ] |

| Post subject: | |

If you are using Windows XP, go HERE and scroll down to ImageResizer, and download the file. Install it on your computer. Then anytime you want to resize an image, right click on the file, it gives you a dialog box that lets you choose a size, then say OK, and it will save a copy of the image with the text (small), if you choose the small size, added to the name of the picture. Either small or medium would be fine for OLF. It will not add a program icon to your desktop, it will just work from the right click dialog box. If you are using a Mac, I know there is a program that is part of the software package that will resize images. Hesh can probably tell you which one. |

|

| Author: | TonyFrancis [ Tue Dec 25, 2007 5:27 pm ] |

| Post subject: | |

test |

|

| Author: | TonyFrancis [ Tue Dec 25, 2007 5:29 pm ] |

| Post subject: | |

Waddy, Thankyou! My appologies to any OLF'ers who found this learning curve annoying.

|

|

| Author: | WaddyThomson [ Wed Dec 26, 2007 1:50 am ] |

| Post subject: | |

Yep. I had never used ImageResizer until I read Todd's entry, above. Went to the site, downloaded it, tried it, then made my entry. It is a pretty neat way to resize images. I was using Picasa II, which is also good, but much more complicated. |

|

| Author: | grumpy [ Wed Dec 26, 2007 6:38 am ] |

| Post subject: | |

I slice up my veneer(s) for purflings with the table saw, zero clearance insert, and the old standby, the 7-1/4" Freud Diablo(40 tooth). I have a sacraficial fence that leaves no room under it. Use a push block the move the veneer forward... |

|

| Author: | SteveCourtright [ Wed Dec 26, 2007 7:07 am ] |

| Post subject: | |

Hey, Mario. I just bought one of the 7-1/4" Freud Diablo blades (from an earlier tip by you) and tried it out this weekend. I am a convert. Merci! |

|

| Author: | grumpy [ Wed Dec 26, 2007 8:42 am ] |

| Post subject: | |

Glad you like it! Had company drop by... Anyway, back to purflings... if you want to thin the veneers down further, and the little blade jobbies(like the LN style one) has too much tearout, if you don't want to drop a C note for one, or if you simply need to make something up -now-, glue some fresh 80 grit(maybe 4 wide x 6" long) heavy back sandpaper(from the thickness sander's stock, for example), and glue it to a slightly wider block. Then, using a second block of the same size, glue narow shims of the required thickness(say, .015" or whatever you wish the final thickness to be) on each lengthwise edge. Now, place your veneer strip on the sandpaper, hold the other block with shims over top, and pull. A few strokes will quickly, and accurately, thin it down, and never a chance of any tearout. I had some wickedly splinter-y mahogany veneer once and made this setup just for that, and never looked back at the blade jobbie. |

|

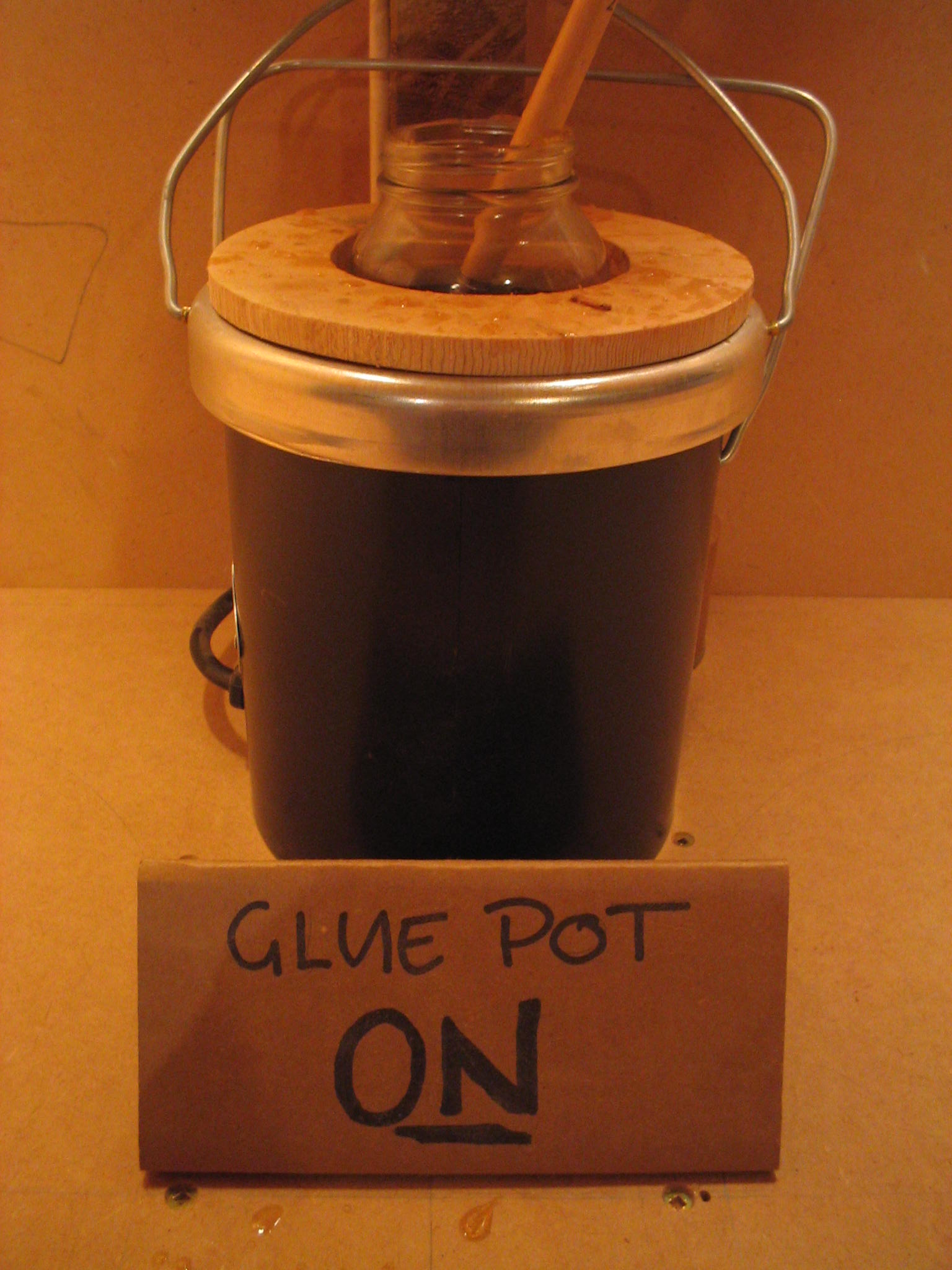

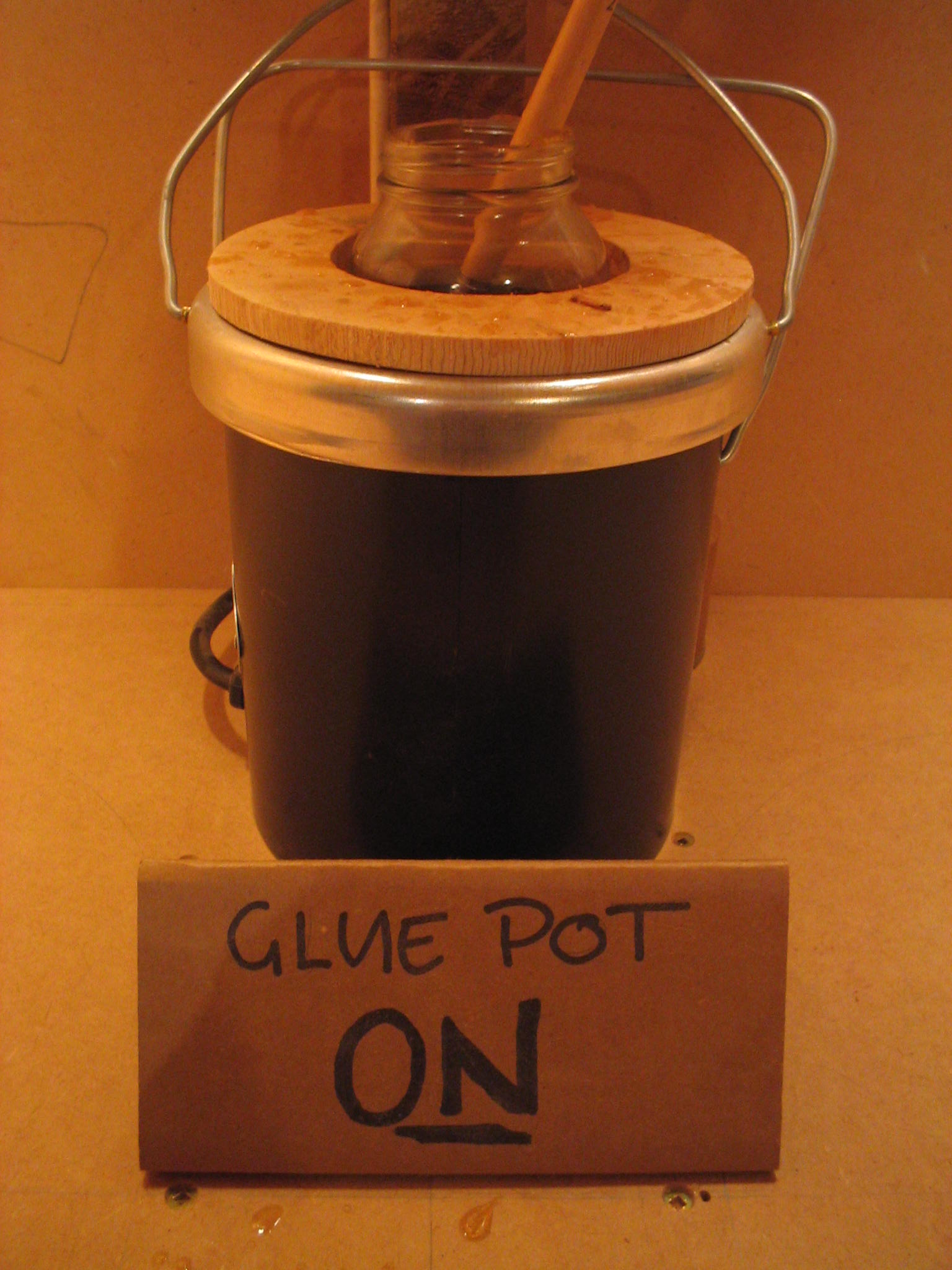

| Author: | TonyFrancis [ Wed Dec 26, 2007 10:38 am ] |

| Post subject: | |

Mario does it a very similar way to me. I Cut the purflings slightly oversize on the table saw, followed by a Lie Nielsen small scraper plane, followed by (a home made but soon to be replaced by the LN) thicknessing blade gauge thingy... Perfect purflings every time much higher in quality and whatever material you choose, as opposed to what LMI Sells. There are some european marqueterie shops that can make something especially for you, but if you only use a few simple woods or unusuall thicknesses, doining it at home is a better option. Even dyeing the purflings is pretty easy too. I know Mario does green dyed holly, and I do black dyed holly myself. For tasks like this (but just about all other hand tool applications), thats why I love Lie Nielsen tools... They offer old style tools of exceptional quality, for a reasonable price. Making your own or finding vintage just isnt an option for most folks. They really open up a wide range of possibilities, like marqueterie making. I guess its fitting too that many people are trying to re-create golden era flattops, now have golden era type handtools. I hope in the future Lie Nielsen starts making finger planes to replace that awful Ibex chrome vanadium junk...

|

|

| Author: | Chris Oliver [ Thu Dec 27, 2007 2:17 am ] |

| Post subject: | |

If you are thinking about making your own purf, check out this tool before spending the big bucks on the LN.  I used this wood strip cutter from MicroMark, on my current build. It took a little practice to get it right. As any slicer would, it really wanted to follow the grain. Many light cuts is the key to getting a nice slice. I didn't get any photos using the slicer, but here is the result.  I used to have an old Exacto one that I used when building model rockets. It disappeared twenty years ago and was probably produced in the 70's. It was a black body with an iron plate and fit (contoured) in the palm of your hand. I would love to have that one back. |

|

| Author: | WaddyThomson [ Thu Dec 27, 2007 3:08 am ] |

| Post subject: | |

I have one of those Exacto ones, but couldn't get it to work very well. I had better results just using a long straight edge and a sharp paper blade in a utility knife. It didn't follow the grain like the stripper did. |

|

| Author: | TonyFrancis [ Thu Dec 27, 2007 8:12 am ] |

| Post subject: | |

Todd, how does O-1 compare to A2? Dave jeske of blue spruce toolworks has been talking about making his paring chisels in O-1 because of maunfacturing difficulties associated with long, thin, A2 blades. Tony

|

|

| Author: | TonyFrancis [ Thu Dec 27, 2007 2:19 pm ] |

| Post subject: | |

Are there other makers using O-1, apart from Dave Jeske's paring prototypes and those funny handled Dovetail chisels by lee valley? To be honest though, after buying my dovetail set (plus a few extra sizes) from Blue spruce...thats all I use for most applications on a guitar, except carving the bridge. Daves A2 chisels are world class. Now all I need is a decent 1" carving chisel for those bridges. Any reccomendations there OLF??

|

|

| Author: | dave jeske [ Sat Dec 29, 2007 5:57 am ] |

| Post subject: | |

Tony, My first full production run of the longer paring chisels is nearly complete. I decided to offer them in sizes 1/8 to 3/4". The A2 and the specific heat treating process keeps the blades nice and straight and the Rc60 hardness is a good compromise for ease of sharpening and edge retention. O-1 is a also a great choice for blades. Some feel that it actually takes a keener edge. I'm not so sure that is accurate, but I find it can be "easier" to get a sharp edge with 0-1. What makes the A2 so good at edge retention and wear also makes it a little harden to sharpen. I use ceramic waterstones with excellent results, diamond is also a good choice. The biggest problem with 0-1 is that it is an oil-quenched steel and is more prone to warping when in thin sections. This can sometimes be minimized with proper fixturing but adds considerable cost. For smaller tools, 0-1 works great and is what I recommend if you are making your own specific-purpose tools in the shop. Hope you all have a great new year; this looks to be a fun forum.

|

|

| Author: | Arnt Rian [ Sat Dec 29, 2007 8:03 am ] |

| Post subject: | |

Hi Dave, let me be the first to welcome you to the OLF! By the way, I am one of the guys waiting for that first production run of paring chisels... |

|

| Author: | TonyFrancis [ Sat Dec 29, 2007 11:19 am ] |

| Post subject: | |

Welcome to the forum, Dave. Glad you are with us! My appologies if I was not 100% with the description of your paring chisels, as posted above. The last time I emailed you about them you were talking of making them only in O-1... I did not realise you were now offering them in A2. Im sure there will be many folks pleased to get such high quality steel and beautifully made chisels in paring length from Blue Spruce toolworks. &n bsp; &n bsp; &n bsp; Personally, I could not be happier with my set! If only there was the wide array of european style carving chisels available in the quality of the Lie Nielsen / Blue Spruce American made tools.

|

|

| Page 1 of 2 | All times are UTC - 5 hours |

| Powered by phpBB® Forum Software © phpBB Group http://www.phpbb.com/ |

|