Here is an example of the conventional solid pins. It's how pins were pretty much always made up until the 30's and 40's.

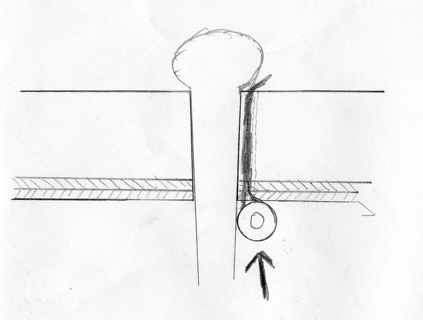

I've never measure the slot depth precisely, but I would approximate the ideal slot depth at the bottom of the hole to be half the diameter of the ball end, plus half the diameter of the wrapped string. When cut this way with a solid pin, the pin will push the ball end in to position, at which point you should be able to remove the pins once strings are up to tension and the strings should stay in place. There will be only direct upward pressure of the ball against the plate, and no significant force pushing it back toward the hole. Excuse the poor sketch from a previous discussion, but if anyone has the software to make a better drawing I would love to have one.

Disclaimer - In this sketch from months back I wasn't thinking quite right and didn't even draw the slot to the ideal depth, but you can imagine what I meant.

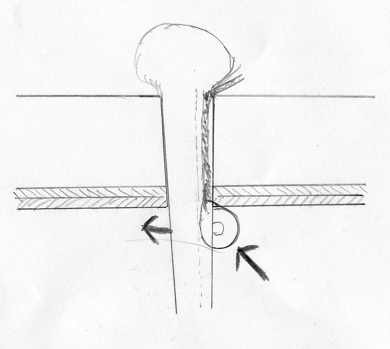

Now when injection molded plastics came available, companies were quick to realize they could save much time in making slotted pins, saving a step in labor. This is what we ended up with.

Now what we have is a number of issues immediately. First is that the ball end can now fit in to the slot on the pin and rest directly against the corner of the pin hole. Second and more significant is that the string is bent sharply at the bottom of the hole, creating a good deal of force pushing directly back against the pin. Again, a poor drawing here, but bear with me.

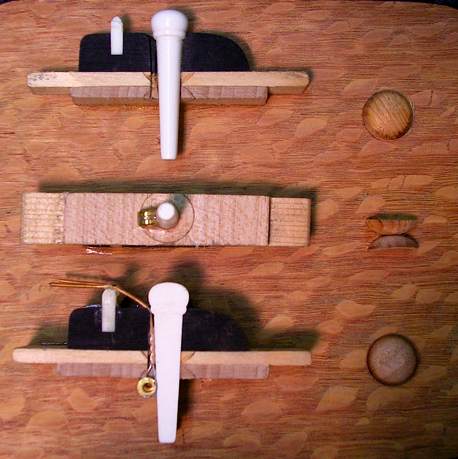

So what happens next is something we all see. Pins begin to wear and dent, and the ball end starts to tear up the edge of the hole at the bridge plate. Here's an example of early stage degradation.

This creates a new force in the picture. The ball end with its round edges and effective tangents when forced in to a hole smaller than it, will begin to act as a wedge. As it is pulled up in to the hole, it will push more directly outward against the pin and edge of the hole, increasing it's ability to cause damage. This snowballs even further when it either cracks the bridge plate, or makes it's way through it to the spruce. At that point there is really nothing to hold it back, and it comes right up to the bridge in no time.

I wish I had some pictures, but for perhaps the first time I can remember in years, I don't have any bridge plate repairs in the shop this week. I had two picked up last week, but none to shoot right now. Oh well, few days go by that I don't have one come in, so I can get some real world shots soon I'm sure.

Here's a 1935 Martin that came in last week. Solid pins originally, and though only four originals were left the owner had the sense to put the slotted replacements in backward.

72 year old guitar, and the maple is slightly compressed. If you can find a guitar half that old with slotted pins that isn't either ravaged or already repaired, you're lucky. You just never see those problems though with traditional solid pins, unless of course someone has replaced the pins with slotted ones which is a double whammy.

You may also note the fourth pin in the above photo is missing. This is testimony to how the strings hold in place well enough with the pins removed. They hold so well in fact, that the owner apparently thought they could substitute one of their pins for an impromptu endpin. Looks like it went in a bit too far though.

Now when the plate gets worn but the damage does not extend in to the spruce, StewMac's bridge plate repair tool is an absolute wonderful thing. Of course I always fit the bridge for solid pins after doing this.

If the damage is up in to the spruce, but the plate is not cracked and the bridge is not split or lifting, then I will often use the more traditional cap.

Or if the repair coincides with the bridge having to come off (which it often does) you can plug from both sides with the StewMac plug tool.

So, solid pins are good. Slotted pins are bad. It's understandable the damages were unforeseen in the 40's when the transition happened. By the time the problems became more widely recognized it was probably already the 70's. Factories in that era and with those production numbers weren't about to switch back to a slightly less efficient production method. At that point they were already a standard, and it's unlikely that many folks buying instruments then even knew solid pins ever existed.

Some people recommend using slotted pins because of their availability, and simply turning them around. This is fine for a builder/owner, but I think it greatly overestimates the knowledge and attention span of the average guitar owner. Eventually, either when the guitar is sold, or more likely when the owner forgets, the pins will start to be used slot forward. This is a worst-case scenario, because it is as though the bridge plate is already perforated, leaving little material for the ball end to have to chew through before it does serious damage.

In summary, please disregard all that I have said above. I am a repair man. If people keep using slotted pins, I will always have plenty of business. Long live the fluted pins!!!