I rarely step in to conversations like this but....

Filippo, I think you may have skimmed Howard's post too quickly and

perhaps misunderstood. What I read was:

"It's right about at this point that Rick often makes a comment about

whether you want to be building guitars or machinery, when there are

factories that do the machinery much better than you ever will."

- In other words "From a pure business and financial standpoint it is

more economical and efficient to buy a pre-existing tool when one is

available, devoting time that would have been spent in creating that tool

toward work in you own trade, at which you are more efficient." - just

some business economics.

"On the other hand, Rick has a long list of orders to fill, and Jim may

just like making machinery."

- In other words "That advice is sound from the perspective of a

professional luthier who is already backlogged to the gills with guitar

work, while for a hobbyist or even a professional who takes great pride in

crafting their own tools, go for it. There's nothing wrong with doing what

you like."

A misunderstanding of Howard's intentions I believe, though the personal

jab was a bit harsh and hasty I think. Anyway, que sera, sera. It's done.

Now, please everyone do me a favor, and talk about thickness sanders. I

think this can be dropped entirely. No more posts about this, Please.

-----------------------

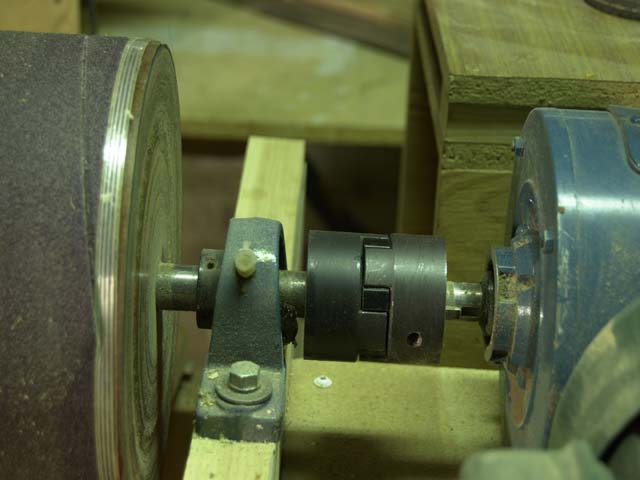

By the way, I think you're right on with a 7/8" shaft, and a 2HP drive

motor should be plenty. If it's too much for the motor to handle, you can

always just slow down the feed.

|