Hello all --

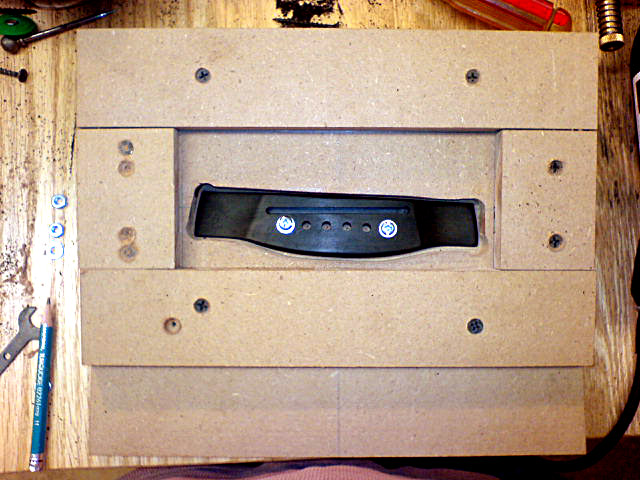

I thought I would put up a couple of shots of the saddle slotting jig I came up with, and hopefully get some feedback on how I could improve the next one. It didn't take very long to build, so for now I'm resigned to just building a dedicated jig for each new bridge design I might come up with. I built in a 10 degree back angle, based on some info from other threads, and used a .125" downcut spiral bit from StewMac in my Dremel. Got some chatter, but that was expected, given the size bit relative to the little dremel. I did get some slight stepping with the consecutive passes, which I can't quite figure out, though I just chalk it up to whimpy tool runout.

One thing that occurred to me halfway through the process is that lowering the action once the guitar settles might be a bigger challenge due to the angled saddle. I suppose if I needed to shave down the saddle, I may just have to either alter the compensation of the exising saddle, or just replace it with another. Does anyone have any experience with this? I'm hoping that the 1/8" width will give me enough leeway to address this down the road.

Anyway, let me know what you think.

Ken