This is that poor old naked cat thing again.......

I used to use the below method with two giant rubber bands available from Stew-Mac. Dan Earlywine's trick is to shim the clamped neck upward about 1/8" to counter back bow when using a water based glue like Titebond. This worked OK for me for many guitars.

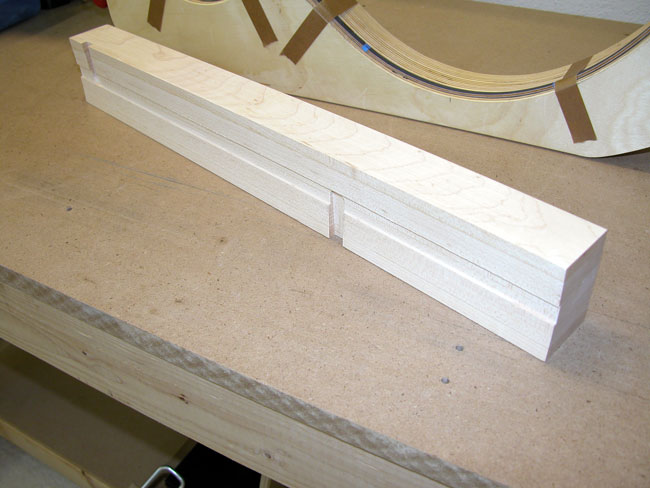

These days I use West Systems epoxy and a custom fret board clamping caul available from Sir John Watkins at CNCGuitarParts.com. This one is a 16" constant radius although other radiuses and compound radiuses are available from John.

Note that no clamping occurs in the very center of the neck where the truss rod slot is and hopefully the truss rod is too..........

And no that is a mistake that I have not made - yet.......

And no that is a mistake that I have not made - yet.......

There are also indentations to clear registration pins. Sorry I have no pics of it in use but it works great and just nails the neck and fret board perfectly flat with the precision of John's CNC and this hard maple block. Highly recommended.