I have now made a note to myself to check that the bearing is tight between each session.

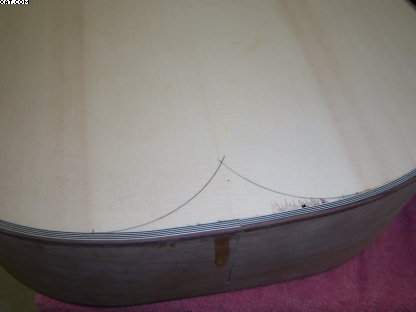

I'm working on #2 tonight and while cutting the binding channel the bearing came off. If there is a positive side to this I would say that it's the location in which it decided to come off. I would think something could be done to make this not look so much like a mistake, but I'm looking for suggestions.

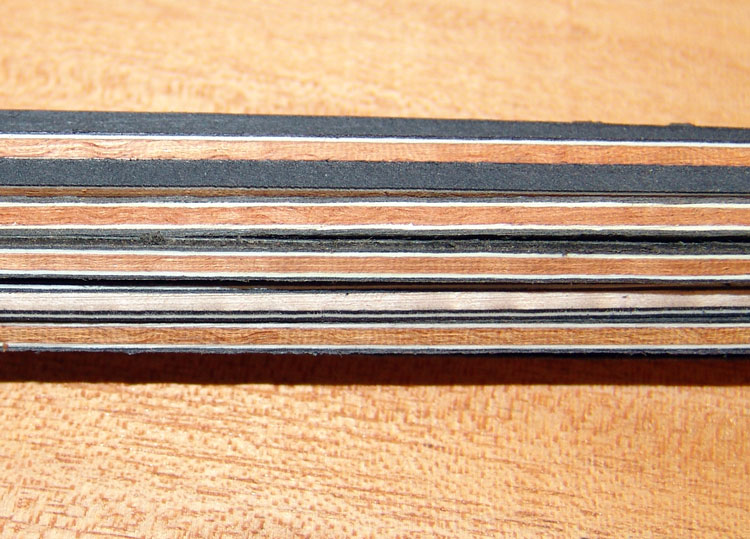

My thoughts so far are to stack up and fill the area with EIR and then come back and route out a design of some sort to inlay over the mistake.

Any thoughts on what I could do? This guitar is for me so anything goes.

Thanks in advance for all comments.

Well, that is if I remember to make sure the bearing is tight. Seriously though, it really does work great and now that I know to make sure the bearing is tight between each session I'm sure I'll not have this problem again.

Well, that is if I remember to make sure the bearing is tight. Seriously though, it really does work great and now that I know to make sure the bearing is tight between each session I'm sure I'll not have this problem again.