Steve, I'm going to give it a shot here, just thinking as I write, I hope this is understandable.

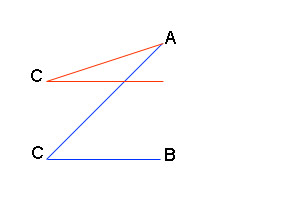

It looks like you are either going to have to taper the bottom of the fingerboard extension or sand away a bit of the top near the rosette/soundhole, essentially creating a taper from soundhole to neck joint. Or, you could make your bridge thicker which will allow you to increase the angle of the neck a tad and have the fretboard extension drop a bit near the neck joint taking care of the gap..... If you choose to sand away part of the top where the fretboard extension lies this might help.....attach the neck to the body at the proper angle, grab a piece of straight/level wood approx. 14-18" long x 3"-4" wide, attach about 6-8" of sandpaper to it at one end, then slide the board on top of your neck(without fretboard....the motion is from nut to bridge), keeping the sandpaper off of the neck and on top of the area where the fretboard extension will go. Watch carefully as you go until the board rests perfectly flat on the neck and the top where the fretboard extension will lay, it doesn't take much so go slowly. With a wider board it will flatten an area wider than the fretboard extension which is good, otherwise you will sand a groove in your top. If the top has some radius here it will help the process if it is flat then you may need to widen your sanding path to taper the top from side to side eliminating any possible grooves. One note, I cannot tell how big the gap is but remember that will translate into an amount to be removed near/over the rosette, your rosette needs to be thick enough or you could sand through....I doubt your gap is that large, if it is I might opt for fretboard tapering or a thicker bridge.

Greg

|