There are various types of yew, English, Himalayan Yew, White Berry Yew and many many others,,,

but Im assuming what you have there is Pacific, or Western Yew.

Ive had a bit of experience with Pacific Yew, which grows from low to high elevations in Western N.A. - Its extremely dense and not yet mentioned "oily". A problem commonly encountered with Pacific Yew is lack of adhesion, on account of this -

This can be remedied by thorough scrubbing of the bedding sufaces with acetone directly prior to gluing up.

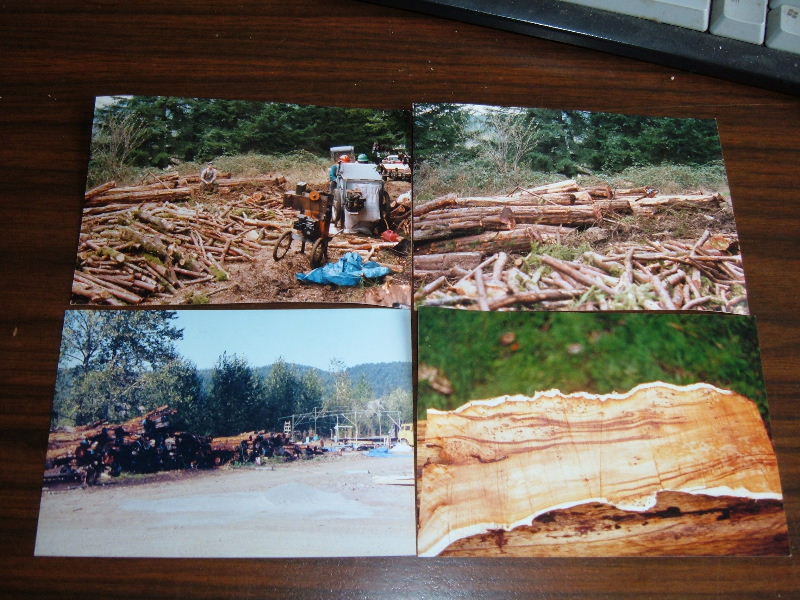

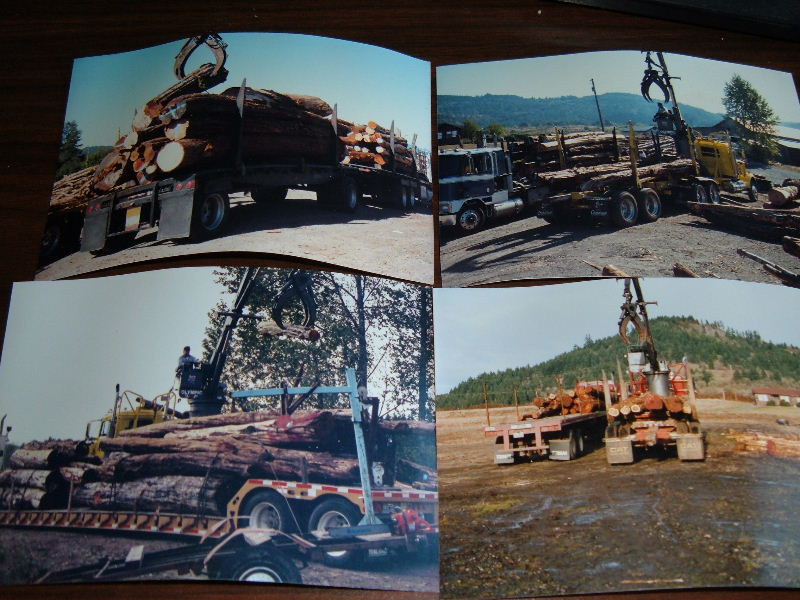

It has always been prized in boatbuilding - and as said was harvested quite extensively in the PNW when taxol was being investigated, the substance taxol as mentioned ,,,was contained in the bark... so sadly the yew would be completely destroyed in the harvesting process,,,

but now a process for semi synthesization of taxol from cultivated yew has been developed.. and if Im not mistaken an actual complete synthesization of the drug has now been discovered... so natural stands of this now rare tree are a little safer.

You may want to look into the acetone scrub method I mentioned - so your guitar doesnt pop apart in a few years...

I would imagine that it might make an excellent guitar - however it may prove to be quite a challenge..

I directed a friend of mine (a boatbuilder) to several massive yews that I discovered in a slash pile on the private property of another firend years ago, and as I recall I never ended up taking any in return... once it was milled!

Soooo I may be able to source some nice clear sides for you,,, if your interested, just let me know,,,

Cheers

Charlie

|

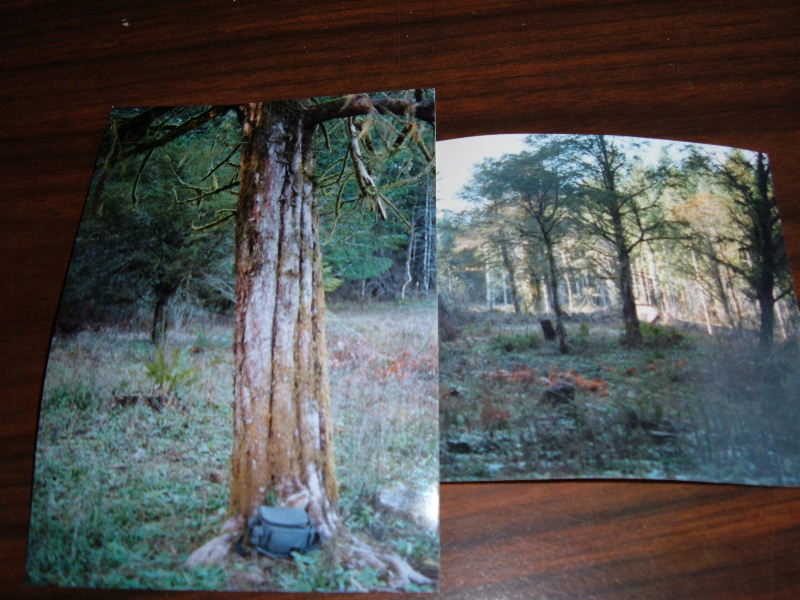

Photo of some standing yews left after logging the conifers which I had purchased. Sorry for the long post..hope you find it interesting.

Photo of some standing yews left after logging the conifers which I had purchased. Sorry for the long post..hope you find it interesting.