AZ - you are very welcome my friend!

James - congrats!! WOW lots of TAS happening out your way.

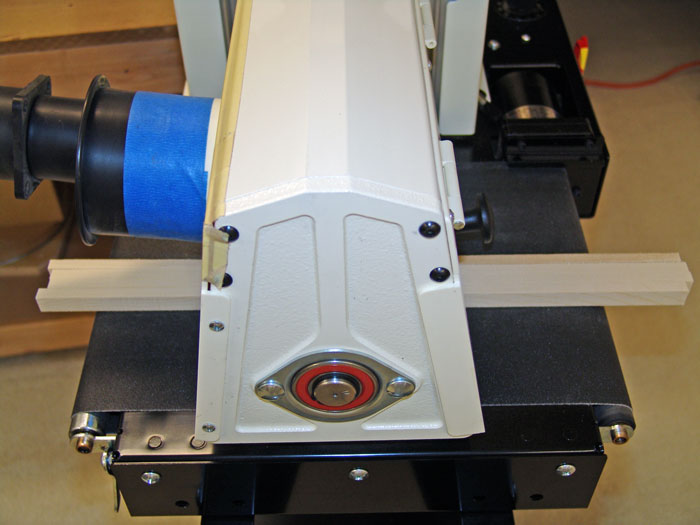

Using you MIDI with the 10-20 I think will work provided that you take very small passes at a time, no more that 1/8th of a turn on the 10-20 crank. Also, the back plate of the hood has lots of fairly open cracks that will benefit from some simple masking tape to help redirect all the suction of your MIDI to the drum.

The MIDI if I recall is something like 94 CFM where the CT-22 is 134ish. All of these specs are rather subjective and dependent on the condition of the filters and the newness of the bag. With a little thinking like for example doing your thickness sanding as one of the first things that you do when you change bags you will be at the maximum performance of the MIDI when you do the tough tasks like drum sanding. I change my bag for every guitar and they tend to be very full with just one guitar. The trick is to keep the drum and paper cool to avoid gumming it up on oily woods like BRW or very hard woods like ebony.

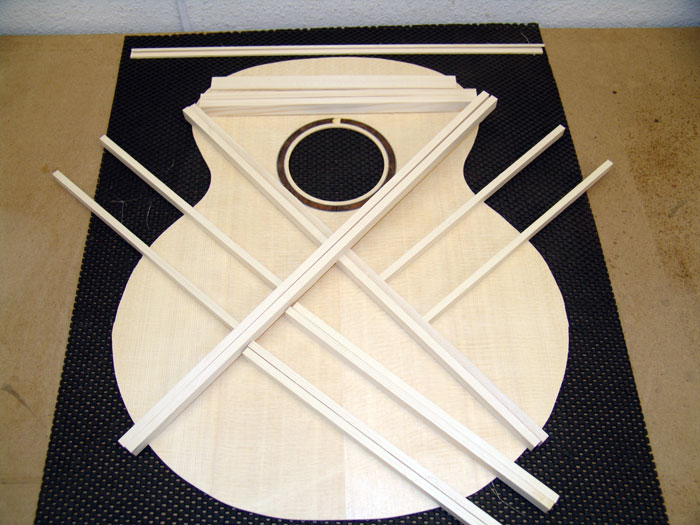

Other things that I do to increase my performance it to cut my plates to the size of the guitar, plus over hang of course, prior to drum sanding so the drum sander has less work to do, less heat, less dust to clog the system.

The out take port on the back of the hood on the 10-20, probably Filippo's too, has a cross member screen type thing probably to prevent large chunks from being sucked into the dust extraction system. With spruce, the fine, clingy dust seem to partially restrict this part of the port. Be sure to stick the vac wand into the back of the port and clean this area very well after a session.

Also, inside the drum are fins. These fins really will hold a great deal of dust and even create a noticeable imbalance in the machine that you can hear and feel when running. this can't be good for the bearings and probably creates some heat too.

So...... be sure to completely clean the machine inside and out including sticking the vac wand near the side of the drum where the fins are (both sides of the drum) and you will see tons of dust being sucked out into the vac. The top of the inside of the hood cakes up too with dust and I believe the lack of a smooth surface here also inhibits the performance of the vac with a drum sander. I stick the wand up there and use my other hand with a 1" paint brush to sweep the inside of the hood clean and suck it all up at the same time.

Remember you are asking a guy who opens both door on his band saw and vacs the inside after every use......

When I am done cleaning my machine I plug the vac back into the machine and turn it on for a minute to get the rest of the lose dust and then push it into the closet.

Pay particular attention to installing the paper on the drum sanders. It is not that easy to get right but very important that you do get it right. The directions with the Performax are good and if you follow them you will have no problems.

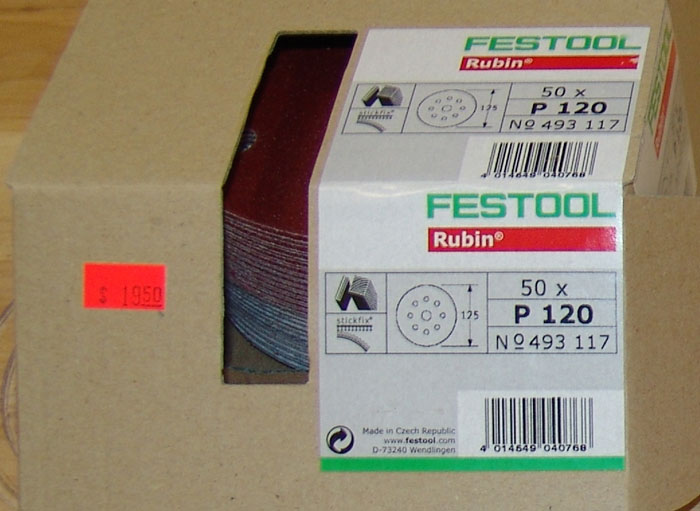

Also, my condo has very early tripping of the circuit breakers. So when I run my 10-20 and the Festool vac if say the dehumidifier clicks on at the same time I trip the circuit for the room. You can either experiment with what you can have on all at once in your shop or consider running as short as possible a high quality/rated extension cord from the 10-20 down the hall and plugging it into another circuit. That is what I do.

As for the turtle I set my vac in the middle or less when using the ES 125 and Bobs your uncle.

As for the power feed I set it on the 10-20 to 30 for nearly every thing and I only use 80 grit for hard woods and 120 for softwoods and get great results.

Remember too to pull the key from the machine when cleaning it (or unplug it) and do a dry run when starting to use it. My dry run consists of putting the wood under the drum with the drum cranked up. I then spin the drum by hand and gradually lower the drum until contact is jut barely made. Then I replace the key, use the power feed to pass the wood through, turn on the drum and start thicknessing.

If by chance you have set the drum to low the 10-20 will trip it circuit breaker and you can reset the drum higher, reset the breaker, and start again.

Typically I try to take no more that .005 off at once and my paper lasts longer this way. I have also found that with some hard woods you can pass it through and say get a .005 reduction and then pass it through again and get an additional .003 reduction without ever lowering the drum. So be careful to not remove to much at once. You can always take more off, putting it back on is a trick that I would like to see done

Filippo buddy - Probably not - with your larger drum sander you will be taking nearly twice the wood off at one time and although what I do works for me it is marginal. What you have is probably better too in terms of keeping the drum cooler and your paper should last longer because of the higher CFM rate.

The Festool IMHO would more than cover everything else in your shop but again my concern is your bigger drum sander.

I do wonder though that even though you have far greater CFM at the dust collector lots of plumbing systems that I read about on forums tend to lose some suction at the actual devices for a variety of reasons. Leaky gates, partial clogs that you can't find or reach, etc.

I just keep my 15-16' Festool hose coiled on a go-bar and plug it in where I need it and have adapters on all my tools.

So in your case Filippo I think that a Festool would make an excellent Vac for you and perhaps limit the JDS plumbing that you have to do by just running the JDS to the drum sander.

I hope this helps guys and congrats on the great new tools/shops!!!

|

) over the intake and everything gets sucked up into that.

) over the intake and everything gets sucked up into that.

I picked the masking tape trick up from you earlier in

I picked the masking tape trick up from you earlier in