I made this a few years ago and got the basic idea from the Jim Williams book, but have made a number of changes . Arnt has one similar as well.

I have stuck with my dremel as the power source , so as to not make it too top heavy. Despite what others have said, I find it to have ample power for the job, but I do it in two passes.

I also have the power cord hung from a ceiling hook , so that the unit is not pulled in any direction.

I use the bit shown for the binding ledge , but change to a 1/8 " spiral downcut for the purfling ledge ( shellac the soundboard edge first too ! )

The donut piece I've eventually decided on ( about 1 1/2 " diameter ) , is small enough to not alter the depth of cut , yet wide enough so I can still feel the unit to be upright, with both sides of the donut contacting the surface. With a very small donut , you can easily tip the thing. I have also chamfered the front of it enough to clear the back/top radius.

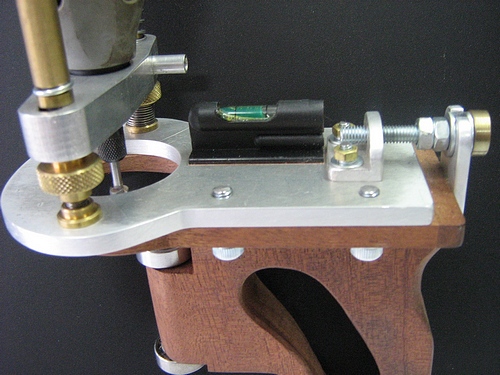

This unit utilizes the top half of my Stewmac router base , which I simply unscrew when required . It is micro adjustable in hieght ,thanks to Stewmac , and also micro adjustable in cutting depth. I undo the four hex head screws on the underside of the unit , then adjust the alumimium mounting plate ( which rides on the Mahogany base ) to or fro with the adjusting wheel at the end of the unit.Relock the 4 hex head screws.

For the purpose of the photo , I used my already bound guitar as the subject

Also pictured is the platform I use to hold the guitar during this operation. This arrangement allows enough clearance for the bearing to register against the sides and also holds the guitar very firm.

Hope this may help anyone making up a binding jig.

The whole system works very well !

Cheers , Craig Lawrence

. I simply put some masking tape on the side where it had a slight dip . Put on enough that the spirit level once again remained steady .

. I simply put some masking tape on the side where it had a slight dip . Put on enough that the spirit level once again remained steady .