Hi, folks-

"Ship in a bottle department":

Nothing revolutionary here, but perhaps this will be of interest to somebody.

I'd wanted to try a bolt-on neck on an archtop, and since my current 'learning project' is a junker plywood archtop, I figured some details for a method to use. The basic idea has been described online by Jay Harland and others- you need a long allen wrench so that you can work through the endpin hole to tighten the bolts.

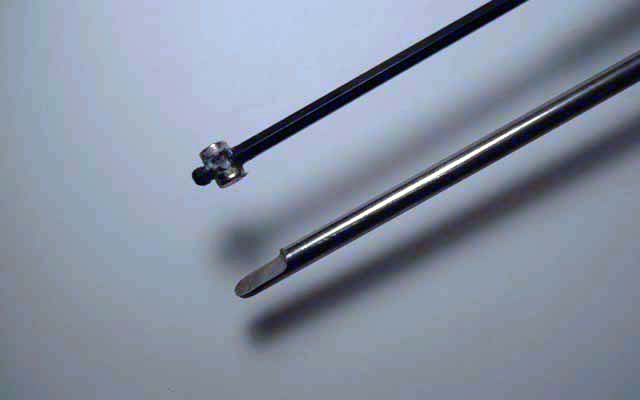

Wrench- Get a section of allen key welded on to the end of a steel rod, and add a T-handle while you are at it. (Friendly neighbor with a MIG welder did this in a few minutes- I built a quick (wood) V-block-type jig to hold the two parts in line for welding.)

Add a couple of rare-earth magnets (LeeValley) near the end of the allen key and fix in place with CA glue.

I'd planned on putting a jack-type endpin in this guitar, so had a 1/2" hole to work through. It makes things easier to have a larger hole- if I were adding a regular endpin, I'd probably plug the hole and re-drill.

Drill- If I'd been thinking ahead, I'd have had my friend weld a 1/4" drill on the end of another rod. However, a few minutes with a rod and the grinder provides a serviceable spoon-type drill, so that I could drill the pilot holes for the threaded inserts in the neck through the bolt holes I'd drilled in the neck block. I found this works better for me than marking the holes through the guitar (pointed rod or similar) and drilling the neck holes separately- though that's how I've done my guitars with 'standard' soundholes.

You need to improvise a way to 'feed' the bolt on to the end of the allen wrench, using the F-hole. Something in the 'coat hanger and chewing gum' department works for me here.

It's useful to have a magnetic pickup wand available to retrieve dropped bolts, etc from the inside of the guitar.

It's a handy technique and saved me a lot of time messing with re-fitting the dovetail on this old guitar- when I finished separating the neck from the body, a whole pile of misc. shims (wood, cardboard) came away with the gobs of softened glue. There was 1/4" of space around the dovetail for 'adjusting' with shims- they don't make 'em that way any more!

Cheers

John