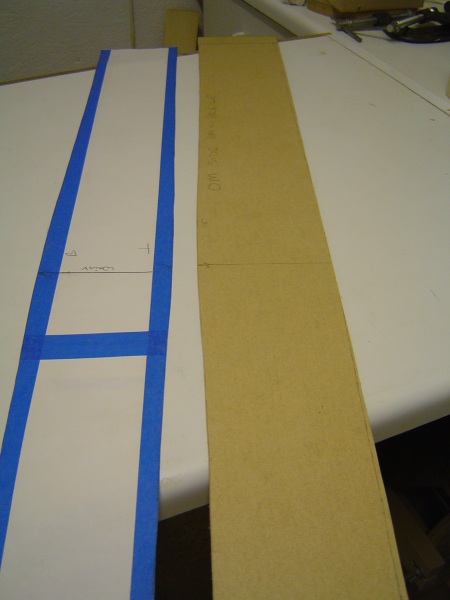

I too profile the back but leave the top flat before bending, just because this makes it easier to ensure the slat is square in the bender.

When the sides are bent and joined by the head and tail blocks then I'll use the stiff paper profile with both the back and top profiles on it, taped to the sides and draw in the profile for the top, plane to the line.

Then the linings are glued in and back and top dish sanded to bring the linings to the right shape. This only takes a minimum of sanding.

Colin

) but I would think that functionality is in there somewhere.

) but I would think that functionality is in there somewhere.