I had a couple of people ask for some jig pictures, so here are three of my setups.

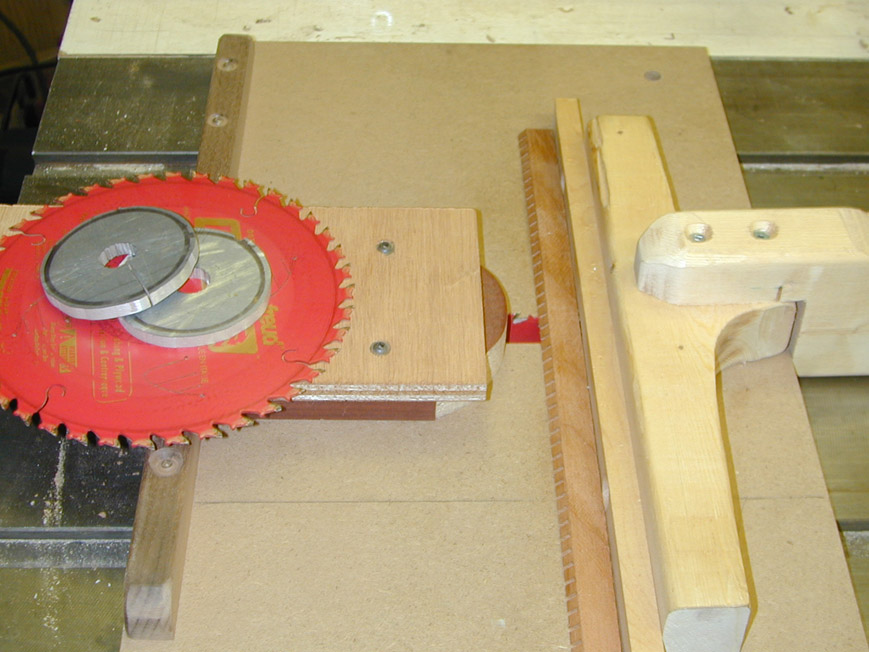

First up is the kerfed lining sled I use for the tablesaw. It runs in both mitre slots, and if ti where actually in use, all three Diablo 40T would be on the saw's arbor, separated by the aluminum spacers shown. The key to the jig is to get the locator pin in the right spot. The pin is simply a nail filed to the correct width for the saw kerf. It is jammed into a slot on the fence behind the kerfing in the pics. So, first make one 3 slot cut - then move it over, and onto the locator pin, such that the last slot is the only one in the cutting area. Line that slot over the last blade, then clamp the fence in place, and screw it into the bigger back fence - now its all lined up and ready to go.

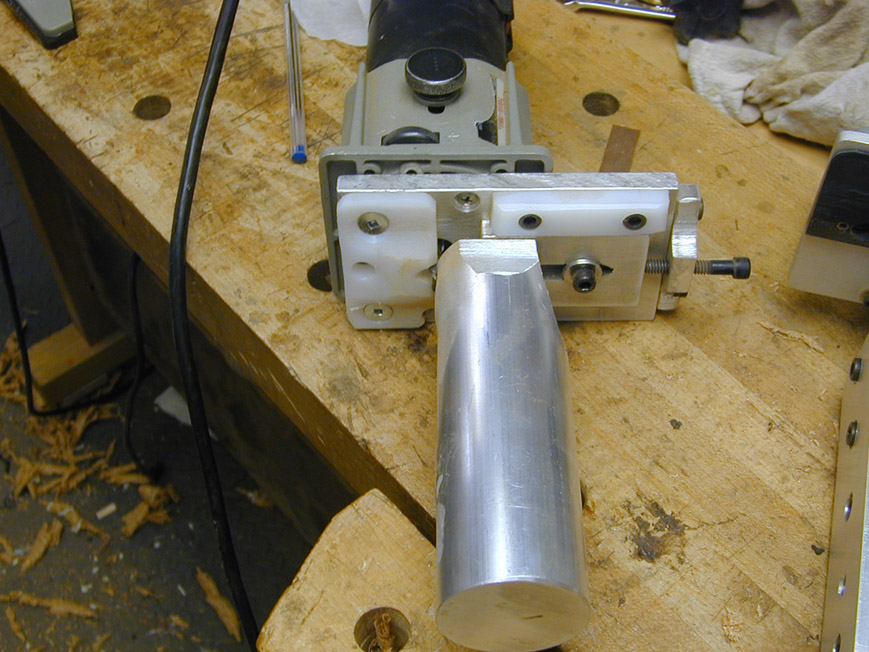

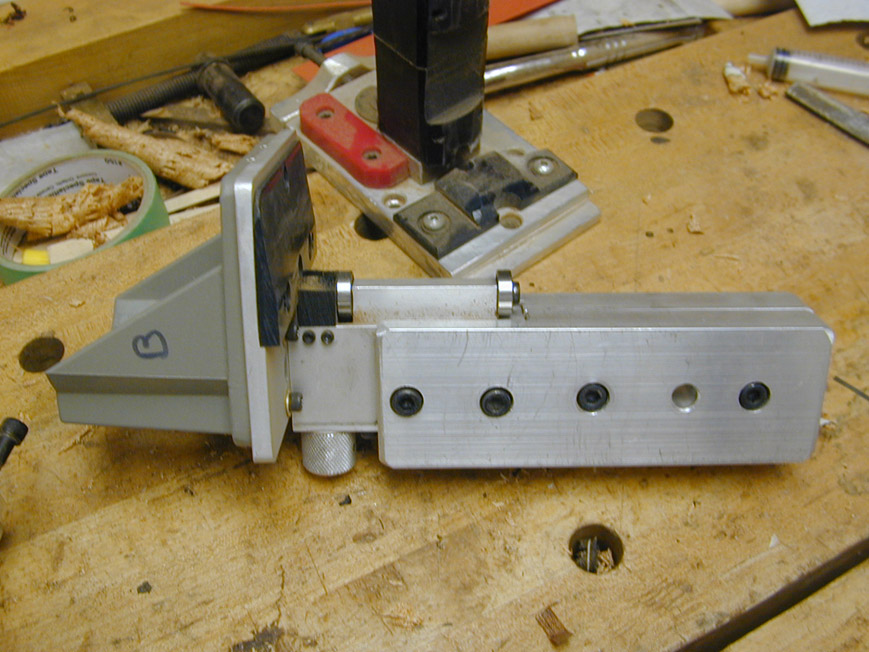

Ok, next up is my version of the binding ledge cutter, and the mod to the Luthier Tool version - I added abig aluminum bar handle to it , to couterbalance it in use. The jig with the big round fence is my binding ledge jig - its always set to cut an 85 thou deep ledge, at whatever height is needed fo the binding in use - you set that with the bit depth, not the jig. I now have 5 PC lam trimmers, this jig has one permamntly ready to go. I used to have only one, the black UHMW one in the pic, and got tired of adjusting to the same setting for binding. No more ...

All the hardware is 1/4-20, easy to find. The bolt out the back end is the micro adjsut for ledge width.

In use, I have the body mounted in a guitar vise, big enough to handle a jumbo in there sideways. Yes, I have to reposition the guitar 3 or 4 times to get around, but I am used to this way, and can route the binding ledge in about 3 minutes. The couterweight added to the luthier tool jig makes it WAY easier to handle and stop fom tipping. It now feels more like my own. I use it for purfling ledges only, as well as the other black jig. 1/4 inch downcut bits, climb cut all the way around keeps the ledges clean.

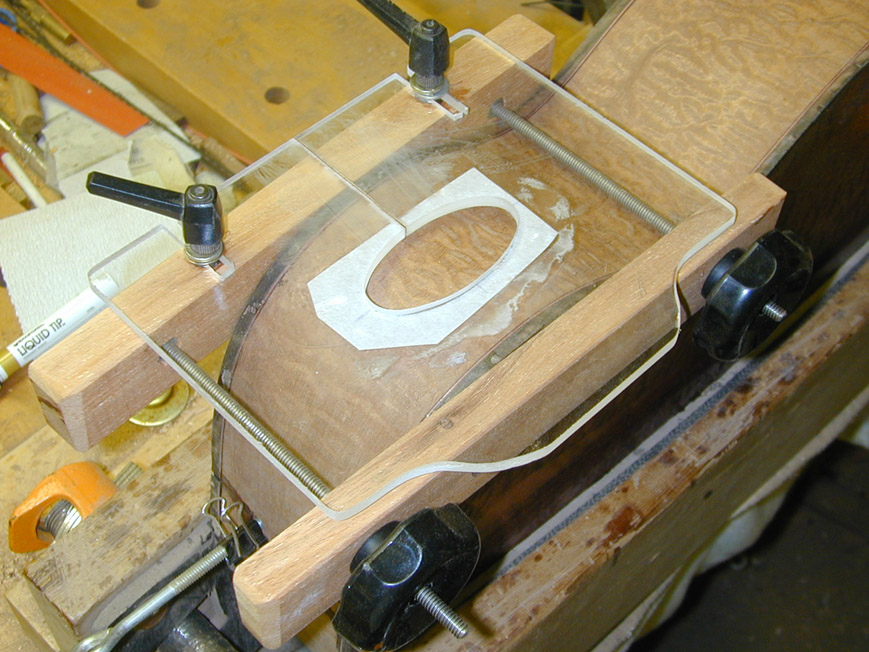

Lastly, a jig to route sideports. I borrowed the clamping setup from my tail wedge jig, its the same idea. With this one, I can make new shapes in plexi, cut the clamping notches and go. It allows the hole to be positioned pretty much wherever you want it, plus by using different bits and guide collars, you can change the size of the port as you wish. I generally use a 1/2 inch guide and 1/4 inch bit, and get an elongated egg shape of sorts with this template.

- pomele sapele, and the binding is curly macassar ebony- tough to see curl, but believe me its in there. This ones a 00-13 fret for one of my sons to have as an heirloom. Until I give it to them though, its MINE to play

- pomele sapele, and the binding is curly macassar ebony- tough to see curl, but believe me its in there. This ones a 00-13 fret for one of my sons to have as an heirloom. Until I give it to them though, its MINE to play