I hope this poll is clear. Vote the nearest way you do it. Thanks for participating.

| Official Luthiers Forum! http://mowrystrings.luthiersforum.com/forum/ |

|

| To Slot or Not, that is the question http://mowrystrings.luthiersforum.com/forum/viewtopic.php?f=10102&t=13735 |

Page 1 of 2 |

| Author: | Bruce Dickey [ Sat Sep 22, 2007 4:43 am ] |

| Post subject: | |

I hope this poll is clear. Vote the nearest way you do it. Thanks for participating.

|

|

| Author: | Dave White [ Sat Sep 22, 2007 4:47 am ] |

| Post subject: | |

Hey Bruce, Not enough choices  I use both pinned and pinless bridges depending on design, custom choice and whim. I use both pinned and pinless bridges depending on design, custom choice and whim.

I'll vote based on pinned bridges. |

|

| Author: | Dave White [ Sat Sep 22, 2007 4:48 am ] |

| Post subject: | |

[QUOTE=Dave White] Hey Bruce, Not enough choices  I use both pinned and pinless bridges depending on design, custom choice and whim. I use both pinned and pinless bridges depending on design, custom choice and whim.

I'll vote based on pinned bridges.[/QUOTE] That should have read customer choice

|

|

| Author: | David Collins [ Sat Sep 22, 2007 4:50 am ] |

| Post subject: | |

If you've done repair for long enough, you know the inevitable damage slotted pins cause. They were a simply a production labor shortcut that started seventy years ago and stuck, with unanticipated consequences. |

|

| Author: | old man [ Sat Sep 22, 2007 5:32 am ] |

| Post subject: | |

If the pin fits the hole, I can't see, at all, why a slotted pin would cause or allow more damage than unslotted. Ron |

|

| Author: | grumpy [ Sat Sep 22, 2007 5:43 am ] |

| Post subject: | |

Oldman, because less of the ball is in contact with the bridge plate, thus concentrating the wear. |

|

| Author: | burbank [ Sat Sep 22, 2007 7:00 am ] |

| Post subject: | |

David, If you could get that set of pics you'd mentioned in the other recent thread on bridge pins, it would become crystal clear. |

|

| Author: | David Collins [ Sat Sep 22, 2007 7:54 am ] |

| Post subject: | |

Okay, my camera is busted so bear with me on the really bad shots from my laptop camera. Hopefully it will be enough to get the point across. I can also only type so many lines before things get wacky with my Safari browser and the forum software, and images won't show. I'l have to split this in to about 4 posts. |

|

| Author: | David Collins [ Sat Sep 22, 2007 7:55 am ] |

| Post subject: | |

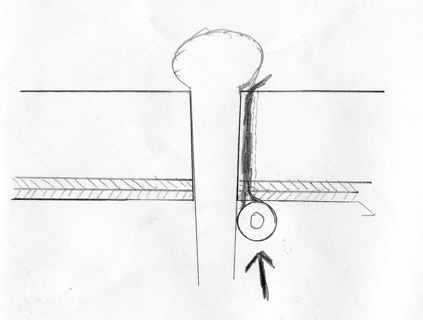

Slotted pins

If the slots are deep enough, most of the force is directly upward against the bridge plate.

|

|

| Author: | David Collins [ Sat Sep 22, 2007 7:58 am ] |

| Post subject: | |

Edit: above I obviously meant to say unslotted. Those are unslotted. Here's the slotted pins

Here there is a good deal of force prying perpendicular to the bridge pin, and the ball end is trying to wiggle it's way in to the hole that it's sitting on the edge of.

|

|

| Author: | David Collins [ Sat Sep 22, 2007 8:00 am ] |

| Post subject: | |

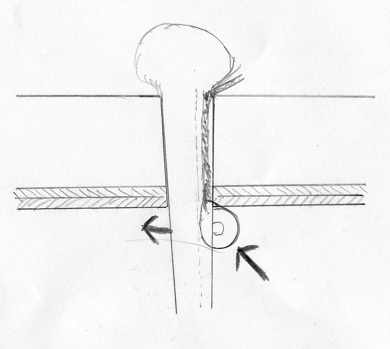

Here's slotted pins after 10-20 years, depending on your luck.

Here's 20-30 years.

|

|

| Author: | David Collins [ Sat Sep 22, 2007 8:02 am ] |

| Post subject: | |

And here's more really bad shots of various repair methods.

|

|

| Author: | David Collins [ Sat Sep 22, 2007 8:08 am ] |

| Post subject: | |

When I get a real camera again I'll try to post a better pictorial here. These are demonstration boards I made so I can explain the repairs I'll be doing to the owner of nearly every guitar that's 20-70 years old (unless it's already been done). It's rare however that this needs to be done to guitars older than 70 years. That's because back then in the days before injection molded plastics, manufacturers used unslotted pins and slotted the bridge. These instruments are usually still just fine. Slotted pins happened out of convenience, and the problems didn't start appearing until they had already come in to standard use for 30 years. At this point it was so standard that manufacturers weren't about to switch back. More builders today however are going back to this style, for good reason. |

|

| Author: | David Collins [ Sat Sep 22, 2007 8:23 am ] |

| Post subject: | |

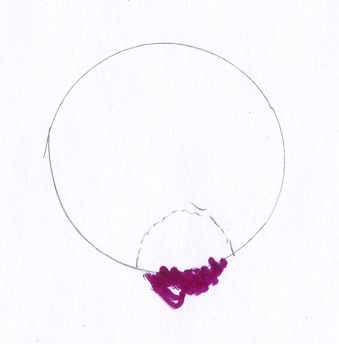

And another thought is where the load is placed against the plate. With slotted pins it's right up at the corner where it will gradually chew away at it.

With the slotted bridge and unslotted pin, the load bearing area will be well away from the edge.

My lack of software, hardware, and digital artistic abilities is a bit embarrassing, but hopefully it was clear enough to get what I was trying to say. |

|

| Author: | Arnt Rian [ Sat Sep 22, 2007 9:10 am ] |

| Post subject: | |

Unslotted pins for me. Let the bridge plate take the load of the strings and the pins keep things in place (and plug that hole snugly)! |

|

| Author: | Jim Kirby [ Sat Sep 22, 2007 9:42 am ] |

| Post subject: | |

No fair, I couldn't vote for the three I've used. |

|

| Author: | Dave Anderson [ Sat Sep 22, 2007 9:48 am ] |

| Post subject: | |

Unslotted are what I've been using for awhile now. I think they are much better .Great pictorial David even if a bit blurry. I see you use the Stew-Mac bridge plate repair tool that Dan Erlewine made. A great tool! |

|

| Author: | SniderMike [ Sat Sep 22, 2007 9:55 am ] |

| Post subject: | |

David, I really like your lacewood background. Seriously, thanks for the great pics, even if they're blurry! |

|

| Author: | grumpy [ Sat Sep 22, 2007 10:27 am ] |

| Post subject: | |

Still, 'they' argue.... Must to give up, David. |

|

| Author: | David Collins [ Sat Sep 22, 2007 10:54 am ] |

| Post subject: | |

When Mario and I actually agree on something, you know it has to be nearly inarguable.

On slotted pins, the load is right on the edge of the hole, trying to bend the pin back and slip up in to the hole. When I slot a bridge, the pins can be pulled out and the strings stay in place. It's like a violin tailpiece. There is virtually no force pushing on the pin, and no wear on the edge of the hole. There are of course still occasionally slotted bridges with damaged plates, but in my experience they are usually due to use of replacement slotted pins. Slotted pins (unless you turn them around) on a slotted bridge are a double whammy, and will kill a plate in no time. The damage is so predictable and consistent in my experience, that I really don't know how any repair tech could determine otherwise. |

|

| Author: | Rod True [ Sat Sep 22, 2007 11:00 am ] |

| Post subject: | |

You know Todd, having worked in an engineering firm for a few years and having a mechanical technology diploma AND knowing that you are an engineer, I can appreciate that you want some engineering-based answers.... BUT....we both know that not everything needs to be answered in an engineering sense to be viable. Anyway, I don't have the answers to this but guys like David Collins and Bryan Kimsey who have done a ton or research and documentation on the use of slotted pins and what they tend to do over time do so I'm going to trust them. Certainly there's exceptions to the rules or generalizations as is noted by your unnamed repair friend. And for someone with such a bent for engineering, I'm surprised at your statement [quote=Todd Stock]FWIW, I ramp and slot my bridges as a matter of course, to include recommending it on repair work; however, I don;t see a good engineering-based reason to do it...it just looks cooler.[/quote] Why would you recommend it on repair work if it has no engineering-based advantage over non-slotted (ramped) bridges. What repairman would ever make money ramping bridges just to make the guitar look cooler

|

|

| Author: | David Collins [ Sat Sep 22, 2007 11:22 am ] |

| Post subject: | |

I was looking back at your drawings Todd (much better than mine btw) and see a few changes that would help demonstrate my point, and may even help explain some of our difference thoughts. First, in the slotted pins notice that the ball end will almost always work a corner in to the slot, rather than bumping up against the outer diameter as in your drawing. [IMG]../forum/useruploads/DavidCollins/2007-09-22_201248_1.jpg[/ IMG] Look closely at the really bad photo of the bottom of the plate on the top left. Notice that the one side of the ball end is more than half of it's diameter over the edge of the hole, if that makes sense. This means that it is not only the angle the string pulls at the ball end, but the ball end itself is actually acting as a wedge with the upward pull of the string. Every small bit the hole wears or the pin dents and bends means that the ball end moving slightly further in. The ball end them makes contact with the hole's edge at a steeper angle, or tangent to the circle, and becomes and even more effective wedge to crush wood and bend the pins. |

|

| Page 1 of 2 | All times are UTC - 5 hours |

| Powered by phpBB® Forum Software © phpBB Group http://www.phpbb.com/ |

|