The best advice I can give if your making a go-bar set up is if at all possible use one attached to a wall using the underside of a sturdy (very sturdy) shelf or similar rather than the four support rods. I have had both types and the four support rods are a pain, they get in the way all the time.

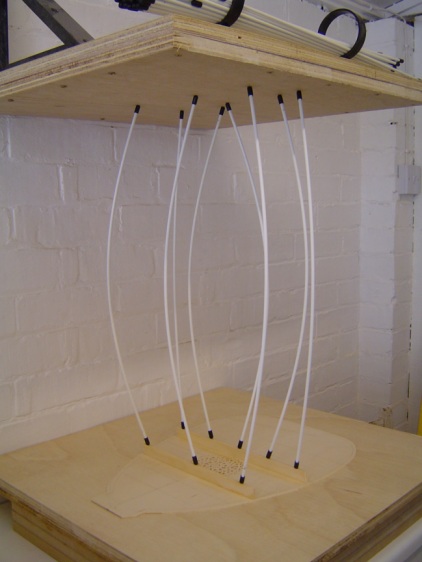

This is my current one which I love to bits, I have clear access for attaching bars etc, it uses 1.5" of ply for the top which is attached to the wall with welded angle iron brackets.

If you mean to attach back and sides as well as gluing braces in the go-bar you'll need to be able to vary the height, the easiest way to do this is to use a raising block under the work.

I set the height of my top the thickness of my radius dish plus the depth of my guitar bodies and then reduce an inch. This means that when I glue on the top or back I have an inch flex in the rods. When bracing tops or backs I use a riser platform that the dish sits on so that I still have a gap of 23" between the top of the press and the material to be clamped, you can see the riser in the photo.

Colin