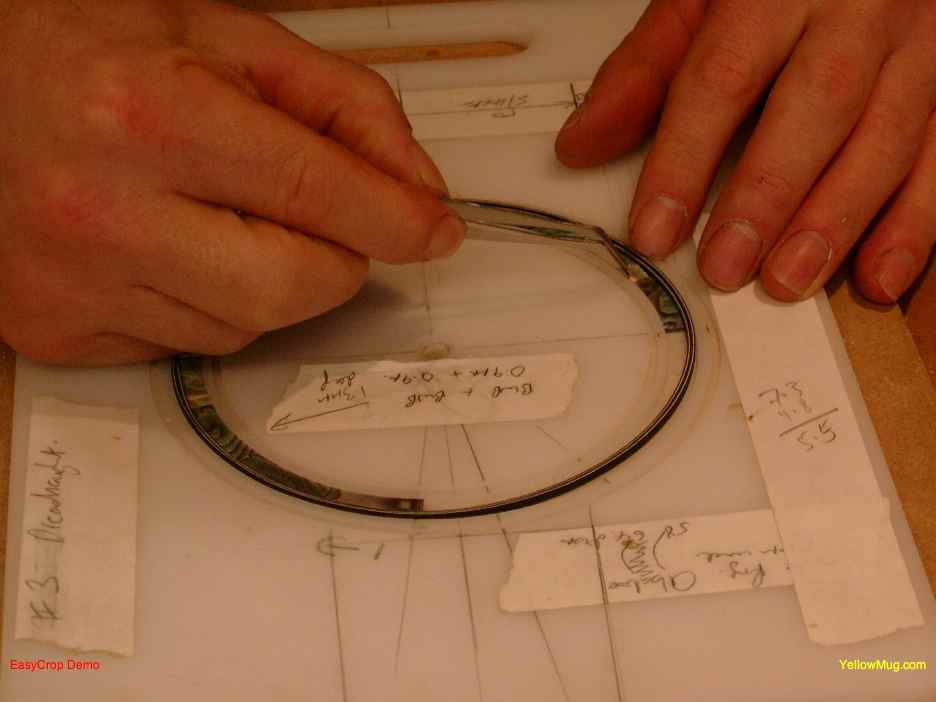

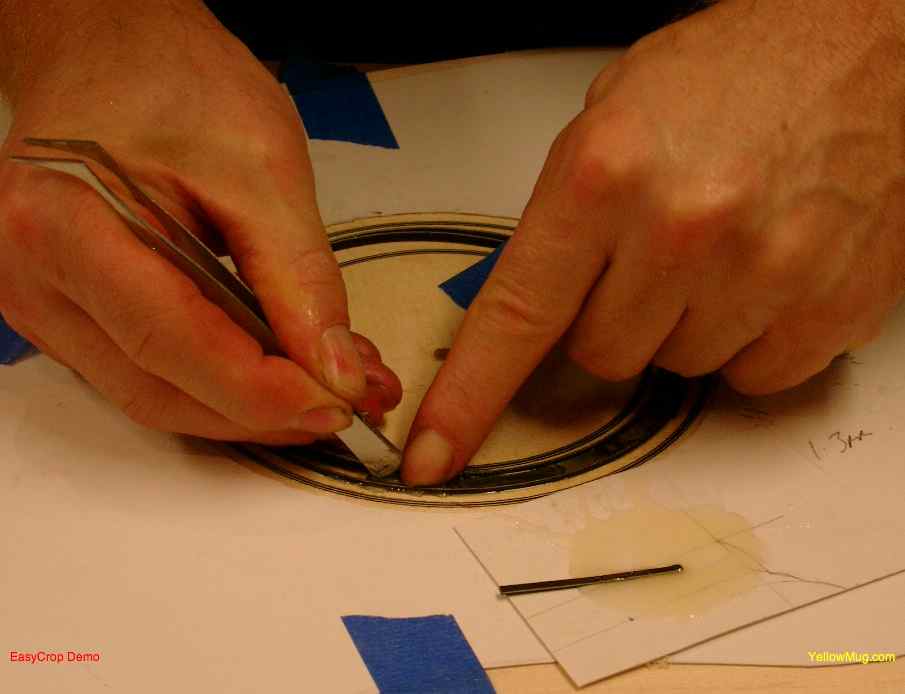

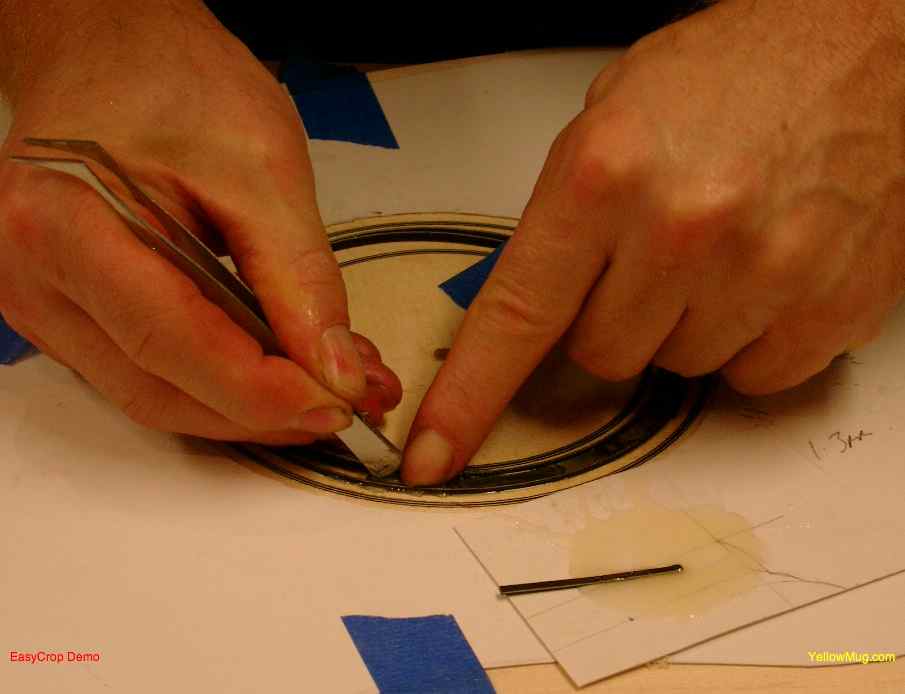

A few pics of the paua rosette going in on my current build..a 12 string. The top is AAA Lutz Spruce from Shane.

| Official Luthiers Forum! http://mowrystrings.luthiersforum.com/forum/ |

|

| 12 string rosette http://mowrystrings.luthiersforum.com/forum/viewtopic.php?f=10102&t=13132 |

Page 1 of 1 |

| Author: | Martin Turner [ Tue Aug 07, 2007 11:53 pm ] |

| Post subject: | |

A few pics of the paua rosette going in on my current build..a 12 string. The top is AAA Lutz Spruce from Shane.

|

|

| Author: | old man [ Wed Aug 08, 2007 1:23 am ] |

| Post subject: | |

Very nice, Martin! Can't wait to see it on the finished instrument. Ron |

|

| Author: | WaddyThomson [ Wed Aug 08, 2007 2:18 am ] |

| Post subject: | |

Nice work Martin. It's fun to see someone actually working on something, and not just a finished picture. That looks great now, but is going to look really great when finished up. |

|

| Author: | Shane Neifer [ Wed Aug 08, 2007 3:11 pm ] |

| Post subject: | |

Lookin' great Martin. What kind of glue are you using? Shane |

|

| Author: | Martin Turner [ Wed Aug 08, 2007 6:40 pm ] |

| Post subject: | |

Hi there Shane, The outer and inner purfling rings are glued in with 5 minute epoxy. The shell inlay takes a bit of time to fit so I used normal expoxy glue for same. I used epoxy because everything was set up for a tight fit on the dry run and I didnt want a water based glue causing the purlfings expanding and causing problems fitting the shell. Cheers Martin |

|

| Author: | Jim Kirby [ Wed Aug 08, 2007 9:17 pm ] |

| Post subject: | |

Very nice. Thanks! I have one of these to do soon, my first, and I'm very much uncertain about the most effective way to get the shell pieces to match up seamlessly. Seems like a good topic for a tutorial! Jim |

|

| Author: | Martin Turner [ Wed Aug 08, 2007 10:26 pm ] |

| Post subject: | |

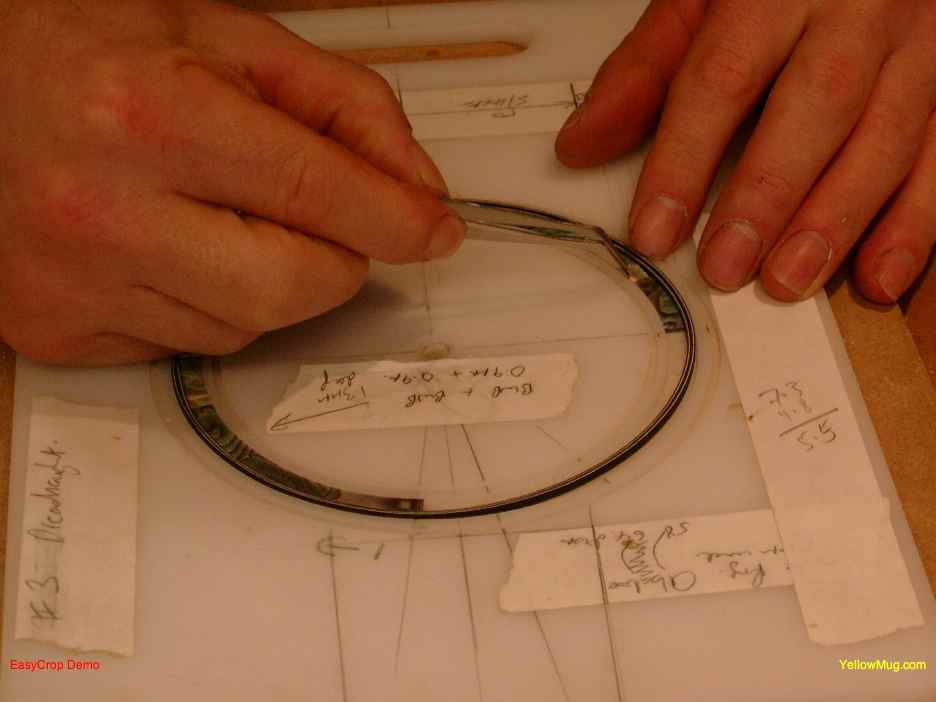

Jim, The dummy run using the chopping board is very useful in helping make sure everything fits before doing the actual job on the top. I forget where I got this idea from. Some lessons were learned during this job: 1. I routed all the channels in one go but in future I'd probably route and fit the inner and outer purflings first and then after scraping down same I'd do the shell inlay. 2. I found that even though the shell pieces fitted flush to the top during the test fit I hadnt allowed for the epoxy lifting the pieces slightly in the trench. I had to a bit of sanding to get everything flush. 3. shellacing the top prior to routing the trenches would have reduced tear out I had in one spot. Doing a manual cut with a paddle pop and scalpel blade (ala Campiano and co) could have also helped reduce tear out. Cheers Martin |

|

| Author: | Jim Kirby [ Thu Aug 09, 2007 6:47 am ] |

| Post subject: | |

But what about getting the shell pieces to fit each other without gaps? What's the most effective way to remove material as needed and get everything to fit perfectly? |

|

| Author: | Jim Kirby [ Thu Aug 09, 2007 6:50 am ] |

| Post subject: | |

Martin, regarding point 2 - If you have enough top thickness to work with, wouldn't it be simpler to recess the shell a little deeper than flush, and then sand the top down to it? |

|

| Author: | Shane Neifer [ Thu Aug 09, 2007 7:42 am ] |

| Post subject: | |

[QUOTE=jtkirby] But what about getting the shell pieces to fit each other without gaps? What's the most effective way to remove material as needed and get everything to fit perfectly? [/QUOTE] Jim, To get teh shell ends to match up I tool a scrap piece of wood (a spare top cause I have a few!) and routed a channel the same rdius as the shell inlay. Then affix two pieces of wood to the top of this piece that you can cut through with a sharp razor saw, I use a japanese saw. Now you have a a basic mitre box. Fasten this lot onto a a piece of flat plywood. Cut through the two blocks and into the scrap top until you have reached a depth below the channel you cut to lay your shell in. Now just lay a poece of your shell into the channel leaving one end so you will be cutting a small piece off. Once you have cut that, slide the shell around the channel until the other end is ready for trimming. Once you have all of your segements done they should be near perfect. For an touch up use 120 grit taped or glues onto a small board and adjust the joint with light sanding if required. Hope this helps, if not, I will post a pic of my jig, that is truley rough in appearance but works quite well. Shane |

|

| Author: | Jim Kirby [ Thu Aug 09, 2007 10:04 am ] |

| Post subject: | |

Shane - That was perfectly clear! Thanks very much. Jim |

|

| Author: | Martin Turner [ Thu Aug 09, 2007 12:29 pm ] |

| Post subject: | |

I do exactly as Shane does. |

|

| Author: | Martin Turner [ Sat Aug 11, 2007 11:49 pm ] |

| Post subject: | |

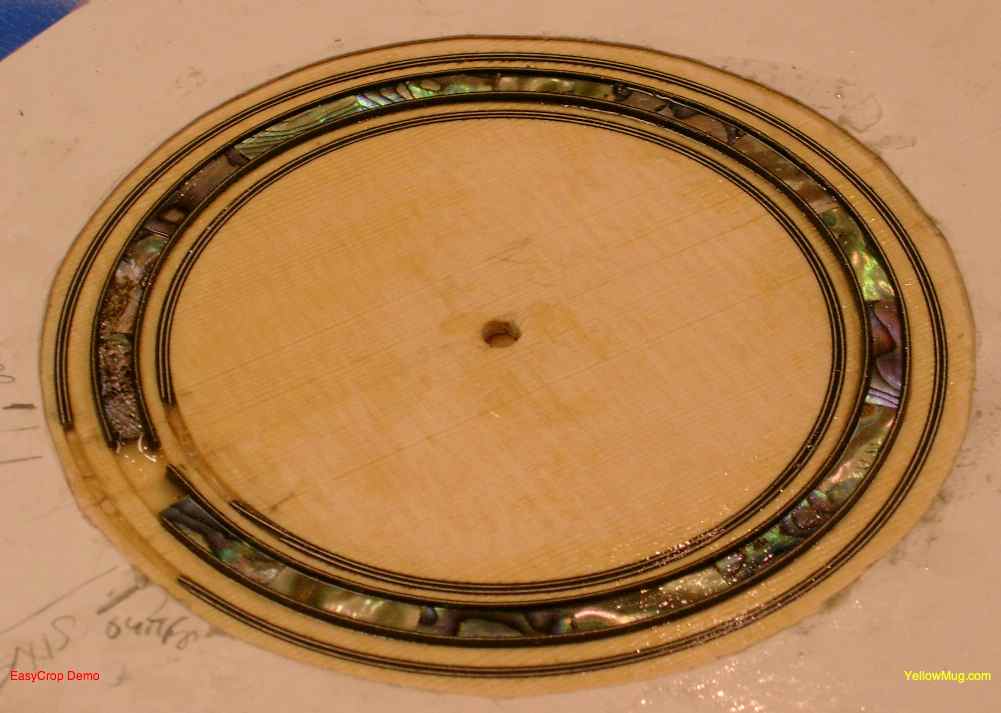

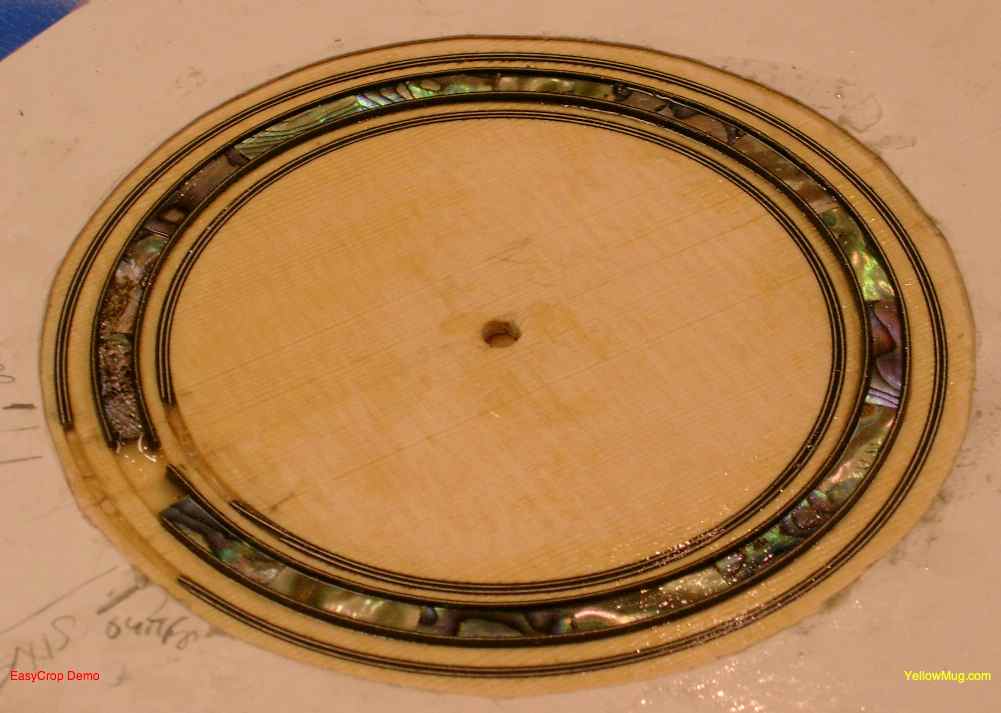

Photo of the finished rosette. Had problems getting a good photo of same without glare from the fluros on the workshop.

|

|

| Author: | Martin Turner [ Sat Aug 11, 2007 11:53 pm ] |

| Post subject: | |

Some of you may have noticed that the last post ditn contain a picture of a paua shell rosette. Its is actually the mitre jig I used to cut the segments of paua shell. Heres the pic of the finished rosette.

|

|

| Page 1 of 1 | All times are UTC - 5 hours |

| Powered by phpBB® Forum Software © phpBB Group http://www.phpbb.com/ |

|