I glue mine up like Hesh does, with the kerfed part toward the side of the guitar. The only exception to this is when I use the "triangle" kind of kerfed linings (which I dont use any more)... for those I expose the kerf's to the inside of the guitar. By gluing it up as a "reverse" lining, it gives a more "clean" look to the inside of the guitar and I also believe that it makes the sides of the guitar a litle stronger. (this may be another fairy tale, but it is what I believe to be true)

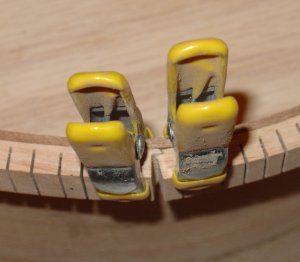

You will find that by placing the kerf toward the inside, you have less of a chance for it to break. I also try to just bend it one block at a time when I am gluing it up. I use clothes pins to hold it while the glue dries. I havent tried soaking the ribbon in hot water... this may be a new and useful trick

|