[QUOTE=Rick Turner]

As for sweeping statements...I think you only need look at the number of "X" braced guitars vs. ladder braced ones selling in the real guitar market to see that sometimes a sweeping statement may carry a majority of truth. I think it's safe to say that at least 99% of the steel string guitar market is supplied with "X" braced guitars.

Walk into any music store that has an inventory of steel string guitars and try to find one that's ladder braced and retails for over $1,000.00.

What? Couldn't find any? Wow![/QUOTE]

Rick,

What's that got to do with the price of fish or the point I made? And keeping the fish analogy it's a red herring. Mass market or niche means nothing to your statement that you need a lot of bracing to stop the top from looking like a potato chip. I humbly disagree based on the ladder braced guitars I have made. We can argue over the definition of what "a lot". Here's what John How did on one of his:

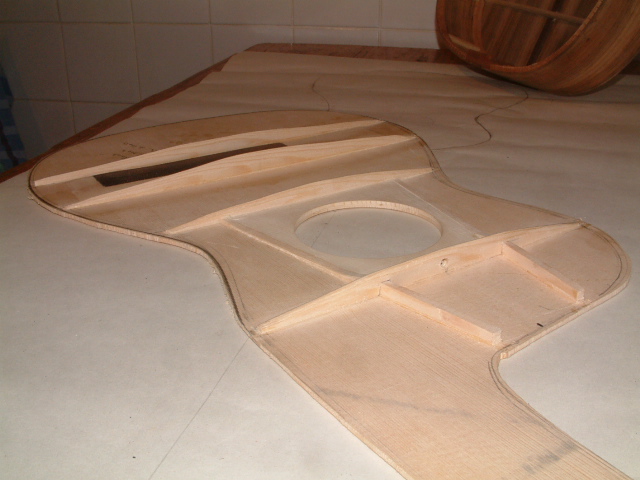

Here's mine:

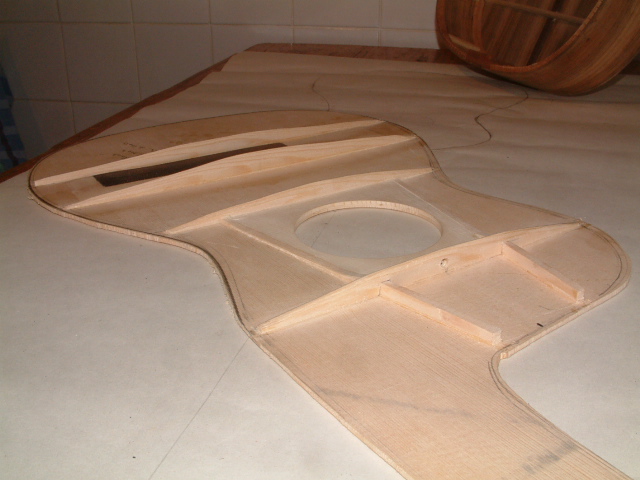

And on my harp guitar (12 strings, 230lbs string pull):

[QUOTE]

We in the ivory tower of Luthierstan can get to thinking of ourselves as being awfully important in the overall scheme of things, but in fact we are the fly on the ass of the elephant in the real guitar world. The real guitar world has pretty much rejected ladder braced guitars for anything other than period pieces or ultra cheap-o's. [/QUOTE]

Rick,

I have no illusions or delusions whatsoever about my importance - I just enjoy making lots of different instruments. You will have to make your own assessment of your importance.

[QUOTE]

And David, while I may not choose at this time to build ladder braced guitars, much of my earliest repair work experience was in fixing them. Unlike many contemporary guitar makers who do not have much time in handling old twisted and broken guitars...which is a great way to find out what works and what fails over time...I do, and some of my opinions are based not only on what I build, but what I've repaired over the years. Given two guitars of equal build quality and similar top thickness, I'd say that a ladder braced guitar is twice or more as likely to need major structural repair than an "X" braced one over a generation or three. That's based on a kind of informal historical record of what's come through my hands in 44 years. Some of that may be because the "X" braced guitars were better cared for, having been perceived as being better quality guitars based on tone.[/QUOTE]

Rick,

Yes a lot of early ladder braced guitars blew up or got destroyed in bar-room fights but so did lots of X braced ones too. As you've said in posts before you can learn a lot from guitars that don't work. If the CF Martin driven X hadn't become the main line of evolution in steel string guitars and they'd stayed ladder braced the builders would have learnt and adapted too. It's a bit like Neanderthal and Cro-magnon man - the Neanderthals didn't dy out because they were stupid.

[QUOTE]

I don't doubt that there is a nice little list of folks making ladder braced guitars, but it's a very specialized market. I would guess that many of the buyers are looking to sound like they had a race change and their music was being played on a 78 rpm record. From a marketing point of view, many of those players do not buy small shop-built guitars; they seek out the vintage ones that are still fairly inexpensive compared to vintage Martins, etc. There are exceptions...the Stella 12 strings, for instance, which are now big bucks. It's a niche market, and it's not likely to grow huge, but I'm glad if some folks can sell hand-made guitars into that market. Just don't confuse a niche with mass acceptance.[/QUOTE]

Back to the herrings rouge again  Also check out the recordings John How has on his website, particulary the one of Jesu Joy of Man's Desire. I'll do some recordings in DADGAD on mine and post them here to. The sound can be just as complex and versatile as most modern fingerstyle guitars. These are NOT (or don't have to be) just blues and ragtime guitars - although they do this perfectly. Also check out the recordings John How has on his website, particulary the one of Jesu Joy of Man's Desire. I'll do some recordings in DADGAD on mine and post them here to. The sound can be just as complex and versatile as most modern fingerstyle guitars. These are NOT (or don't have to be) just blues and ragtime guitars - although they do this perfectly.

[QUOTE]

An interesting side note: some of my favorite guitars of all times are the Howe Ormes which had the cylinder top and ladder bracing. The cylinder top adds tremendous longitudinal stiffness with no weight penalty. That's the direction I'd go with a ladder braced guitar. There are a few problems that show up long term, but they are remarkably robust for such lightly built instruments, and it's because of that longitudinal belly ridge, aka cylinder top.[/QUOTE]

Funny you should mention that . . . guess what I do.

[QUOTE]

As for most of the other ladder braced guitars of that era (1890s), most of them, including nearly all the Washburns, are not really very good sounding guitars. The best of the ladder braced ones...the Stellas, etc. came a bit later, and they didn't have a great survival rate.[/QUOTE]

Ask Martin Simpson about the all mahogany ladder braced Concert guitar dating from around 1915-1920 that he borrowed from me for over 2 years and I have videos of him playing Blind Willie Johnson stuff on that he said was only missing the scratch, scratch, scratch of the 78's

[QUOTE]

It will be interesting to see how well contemporary ladder braced guitars hold up over 25 or more years. I've seen tops look kind of wavy on a couple of the Bourgeois guitars...[/QUOTE]

Could be or maybe not. I'd love to see a survival rate based on population - what percentage of X braced guitars built between 1900 and 1945 are still with us?

[QUOTE]

My inclination would be to go relatively tall and skinny on braces, taper them out nicely to the ends, run the grain with the top grain on the bridge plate, and perhaps even laminate a cross grain piece to it. Also get the neck angle right so the saddle isn't too high off the top which puts a lot of torque in the bridge area; keep that at 1/2" or so.[/QUOTE]

Funny you should mention that . . . guess what I do.

[QUOTE=Howard Klepper]Main problem with ladder braced guitars, IMO, is that with rare exceptions they lack depth and complexity of tone. About the best Stella repros I have heard have been the Fraulinis.

Dave, Dave. It has to stop somewhere. Or it ought to. [/QUOTE]

Howard,

It's a shame we don't live closer for I'd love you to play these guitars. When I made the first one I thought that it would be just mid-range honk for blues and ragtime but the sound is as complex as any guitar I have so far made and I play Celtic stuff on it a lot in DADGAD and other open tunings.

As to the it has to stop somewhere do you mean ladder braced guitars or me writing this to ensure that mis-conceptions don't become accepted fact - a cause from reading his post here that is very dear to Rick.

|