Thanks guys.

Dave, I've thought of getting in to the luthier's tool making business, but

it's just not my trade. Part of the reason I post things here is in hope of

others making them for sale, because quite honestly I only make my own

tools when there's nothing available to do what I need. If someone like

Watkins, StewMac, LMI, etc., were to make things like this I would

probably buy them before making my own.

Peter, I originally wanted to use some straight DeStaCo clamps for the

end, but made the tool over a weekend with just what I had laying around

the shop. Once I got used to the screw clamps I never got around to

retrofitting it with inline toggle clamps. Unlike the main clamps with the

rubber tips however, think I would like to use hard clamping faces. It

seems clamping in this axis is more position-dependent than pressure-

dependent for accuracy. With hard faces I would still have to make end

cauls, but tracing on a chunk of 3/4" pine, band saw and spindle sander

takes perhaps 3 minutes. By now I have a good drawer full of various

headstock shapes on hand anyway.

If I were making a new one I may use the straight line action

clamps you recommended, but for now if it ain't broke I've got plenty of

other projects to keep me busy  . Now I just mark the position of the . Now I just mark the position of the

handle with a piece of tape, then loosen one full turn from the dry

clamping.

I should also note I made this before I had any milling machine, and it's

all band saw, drill press, router and files, so it's a very doable home shop

project.

A few things I didn't realize may not be obviously apparent from the

photos;

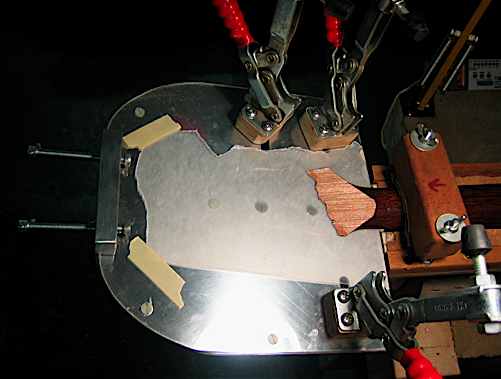

The toggle clamps are mounted through slots in the plate, about 1

1/2"-2" long for adjusting position.

There is a 1/8" clear plexi plate over the the aluminum base plate. I

screwed it down with nylon screws to be careful to avoid anything that

could scratch, although if the heads are properly countersunk this could

be redundant.

The cradle that the neck sits in is a piece of corian (why, I don't recall)

with two strips of 3/16" stiff rubber as rails toward the edges. It also has

a layer of cork over these, although it really doesn't need it. The

important part is that it slides toward or away from the headstock. The

reason is that changing the angle of the plate for different headstocks will

change the position, and I wanted to be able to keep the underside

supported as well as possible. This need could probably be eliminated by

putting the axis on the plate closer to the nut.

The next important update to the tool will be some more adjustable

clamps. Occasionally I will find a cracked headstock that needs a bit of

pressure from the sides at the heel. For this I will probably make some

clamps that just attatch on to the edge of the plate rather than mounting

holes - the needed position varies too much to justify a dedicated

location. It will probably be a screw clamp (out of size/space

considerations) mounted to an arm with a ball joint base. I'll probably just

tear apart a few ball joint swivel vises for this out of convenience.

|

. Now I just mark the position of the

. Now I just mark the position of the