Dr. Kennedy:

I would have replied sooner, but was on the road over to Greenridge in a very welcome rain storm (we've been much dryer here this year than usual... welcome back, El Nino!). Much of this has been touched upon, but worth reiterating:

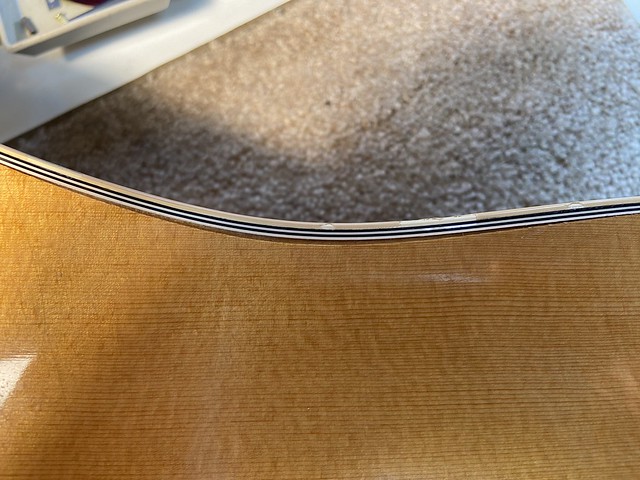

- I suspect the binding and purflings are the usual Bolteron (ABS/PVC alloy), with a possibility of some vinyl purfling lines, and neither material glues well with anything other than an MEKP-enriched plastics adhesive or a good thin CA. If a fair amount of force is required to bring the binding into contact with the channel, I would suggest freeing the binding and loose purfling up to the neck pocket (top) or heel cap (back), then conducting a check for loose adhesive or other debris. If the neck must come off to free the binding, we add that to the bill, as any piecing in of material tends to be highly visible outside the fretboard extension/heel cap area.

- We tape the binding and purfs in using a strong, high-tack tape like the 3M green, then tack the binding/purfs in between the tape segment with BSI CA Super Gold thin foam-safe CA. If you are both quick and careful, you can get glue into the joint, then wipe off the excess towards the edge of the instrument... this CA is not as 'hot' as other CA adhesive, so other than a small amount of scoring on lacquer - and nothing at all on poly - cleanup is a very light scrape and sand with some P800 and 1200. We have found that touch-ups on Martin or other lacquer- finished guitars are often unnecessary if the repair is carefully done. The tape may be removed now and the joint inspected for spots where an additional tack is required. When tacking, it may be necessary to alternate between top and side as you work along the length of the loose material... and that may require rotating the guitar around to keep the fresh CA from flowing where you don't want it. Also worth noting that the amount of glue to tack things in is far less than you would think necessary, so more frequent, smaller tacks are better than less frequent, farther apart tacks.

- Do not allow the CA to flow into the tape... that may cause a hard edge that requires careful scraping or on low-quality tape, my actually glue tape to finish.

- When following up the tacking of the binding and purfs, work 2-3 inches at a time and keep a supply of fresh, clean paper towels handy for wiping up.

The usual careful scraper and wet/dry cleanup should allow a buff without additional clean-up. If you are lucky, the finish is polyester or polyurethane and any big boo-boos can be cleaned up with CA remover.

Good luck with the repair! I have a Thompson and a Huss waiting for me in the shop, so headed down.

WR,

Woodie G

|

IMG_8572 by Terence Kennedy, on Flickr

IMG_8572 by Terence Kennedy, on Flickr IMG_8573 by Terence Kennedy, on Flickr

IMG_8573 by Terence Kennedy, on Flickr