Does anyone have pictures of the Todd Stock side for jig? All his posts are removed and I see everyone’s responses but not the jig.

If anyone else uses a jig for this and is willing to share I’d like to see how to improve or rebuild this. The results were good, but this idea assumes the board is not a compound radius (I don’t use that today). The one I saw online top mounted so you could align however you want.

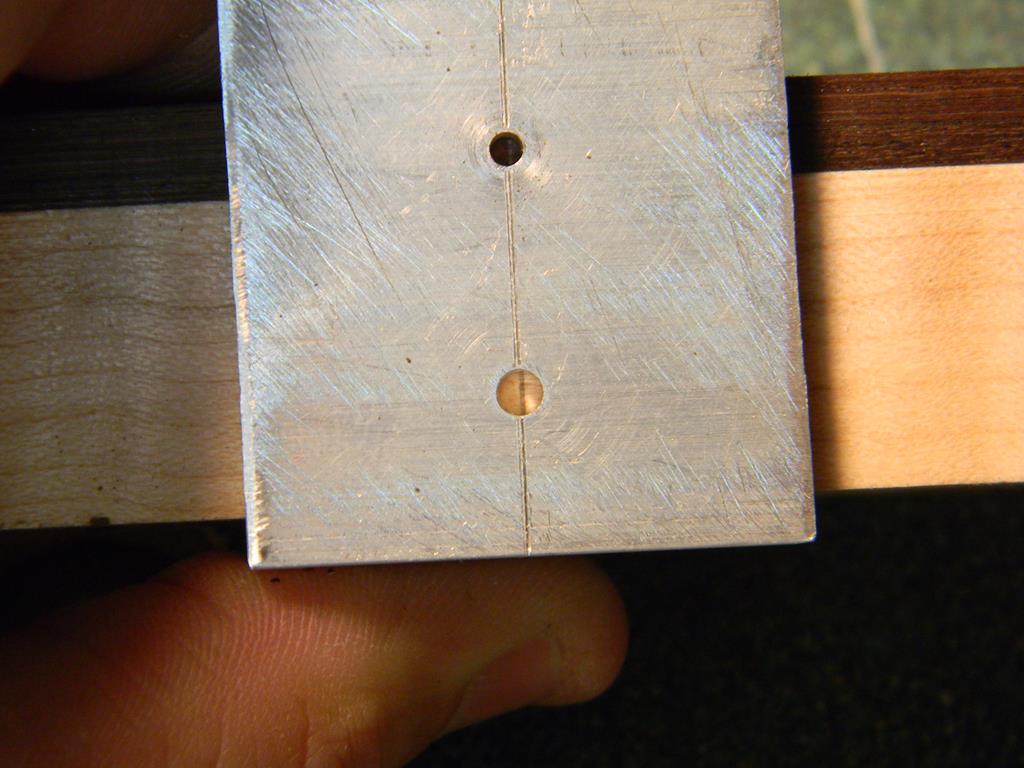

I use this guide block to align everything first:

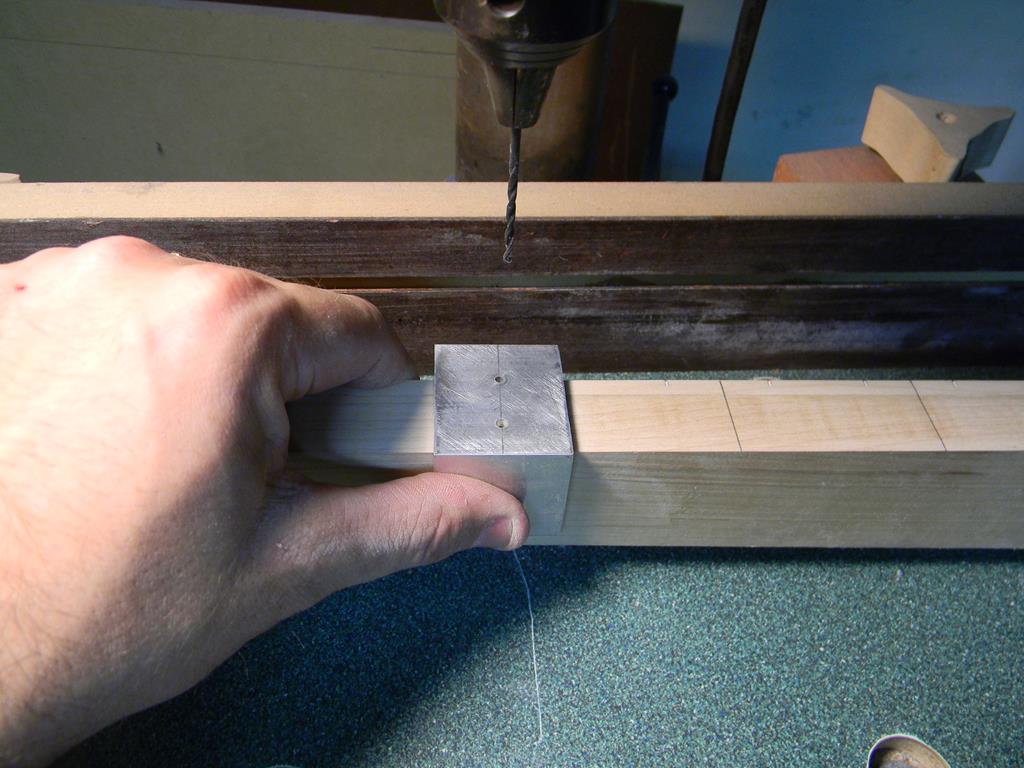

The board is attached to a sled with double stick tape:

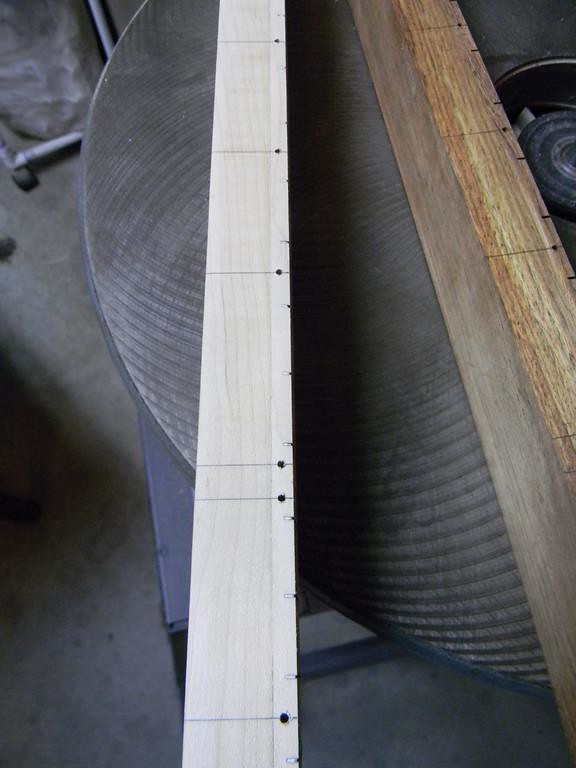

Each fret position is marked with an indexing pin:

Some pics of halo markers. One is a silver ring filled with ebony dust, the other is a silver ring filled with standard 1.5mm white plastic side dot material in the center:

Sent from my iPhone using Tapatalk

.

.