So here’s an idea that is, I’m SURE, more complicated than it is worth.

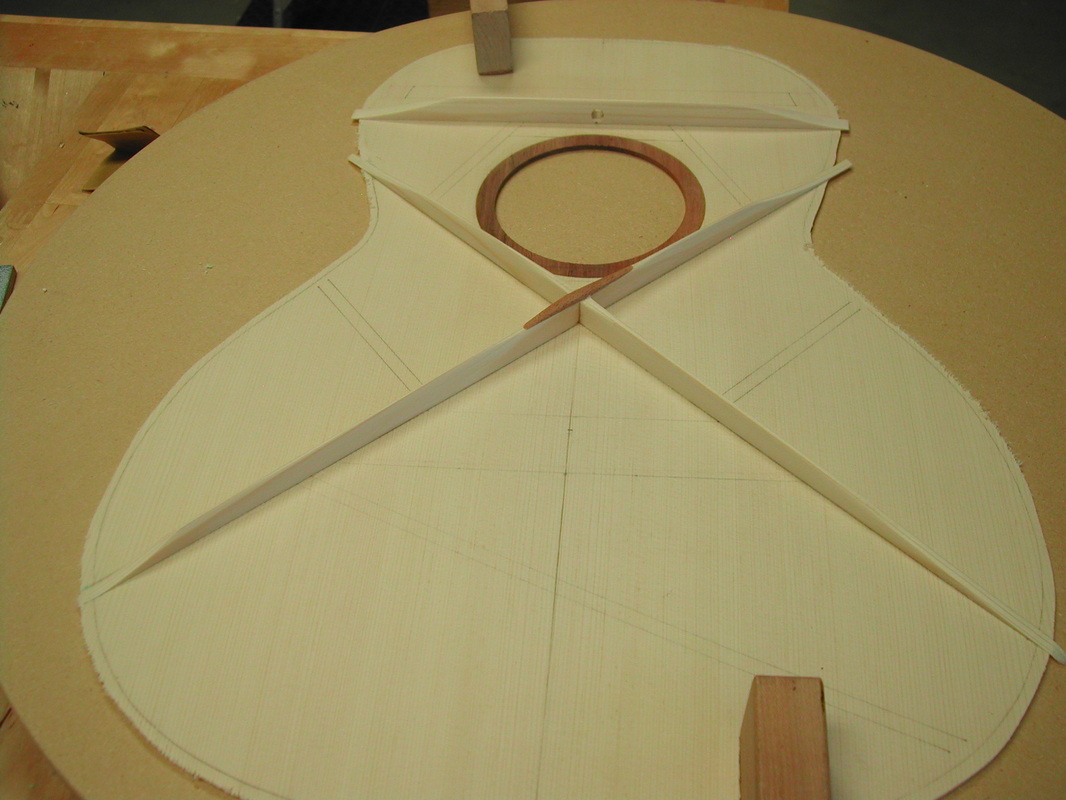

I’ve seen some folks reinforce the soundhole area with a solid ring on the inside. Some do the traditional thin “braces” on 3 sides and I’ve even seen some attach binding to the inside of the ring to seal off the end grain.

So I wonder... has anyone done like an “insert”?

What I mean is a round reinforcement that will be under the soundhole, but also has a raised lip that inserts into the sound hole and comes flush with the top.

I’ll include a REAL bad drawing to farther complicate things here

Check out this art!

Sent from my iPhone using Tapatalk Pro

![Dead [xx(]](./images/smilies/smiley11.gif)

![Thumbs Up [:Y:]](./images/smilies/smiley20.gif)