Hello everyone!

I'm a recent member to this forum. I've been doing a lot of digging and reading and there's certainly a lot to be learned. However, I'm looking for your personal insight here.

Just a little bit of background info: I've been repairing guitars for the last 10 years as a self-taught technician. I've studied Electronics Engineering, so I also work on tube amplification, effects and I also work with electric pianos (rhodes, wurlitzers, etc.) on occasion.

I live in Portugal, where the music biz is not much of a deal, but there's not too many people doing what I do. Those who actually work on guitars are amateurs, so I've got a headstart here. Last March I flew to the United States to learn all that I could at the Galloup School of Lutherie.

I'm about to move my shop to a big city with a fairly decent music scene going on. I'm also about to buy lots of powertools and machinery so I can approach any repair work and also start building acoustic guitars as soon as possible.

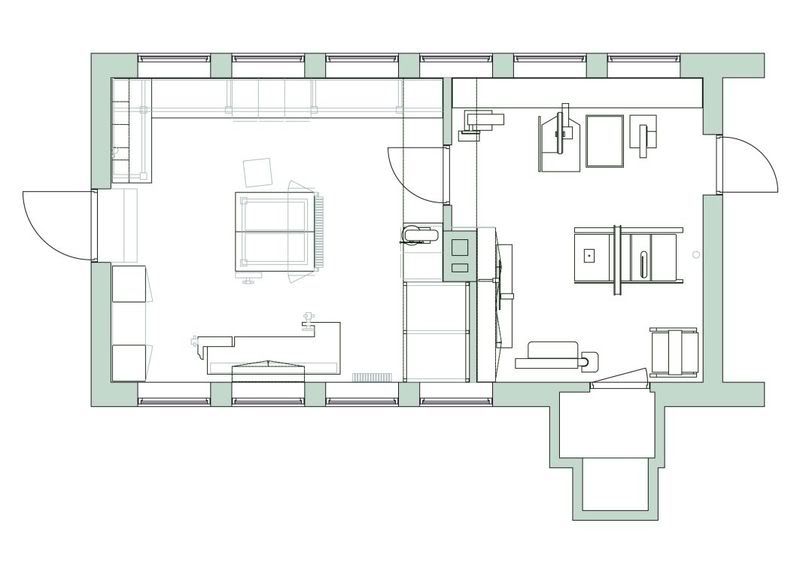

This the space that I have at my disposal:

The room on the left is where the majority of the repair work will be happening. There's also a small office where I can deal with all the paper work and also make use of all sorts of equipment for plate tuning (signal generator, strobe tuner, etc.).

On the right, there's the "piano" room, which is just there so you can have an idea of the size of that room. What I would like to know is what are your thoughts and feelings towards the list of powertools, the layout of the shop and your suggestions for a nice band saw with resaw cappability.

Ultimately, I would like to see this thread as a cool introduction to shop layout and business management when it comes to investment.

I'm sorry for any eventual grammar kicking. English is not my main language. Feel free to point out any blatant mistakes.

Thanks in advance,

Celso

![Thumbs Up [:Y:]](./images/smilies/smiley20.gif)

- and a oven for kilning purposes). By the way, those inconspicous fire hoses are supposed to be a buffing arbor. I didn't find anything similar in ArchiCad.

- and a oven for kilning purposes). By the way, those inconspicous fire hoses are supposed to be a buffing arbor. I didn't find anything similar in ArchiCad.