After some recommendations from some folks here, I got my old Laguna 16 (Meber) set up with the new ceramic guides. This Meber model saw leaves a lot to be desired but it's working.

My goal was to get this dialed in well enough that I could get 3 back sets (6 pieces) out of 4/4 lumber. One of the problems I've run into in the past was wandering cuts due largely to the ripped piece cupping against the fence and putting sideways strain on the blade. I devised this sled to try to get rid of that problem and so far, so good.

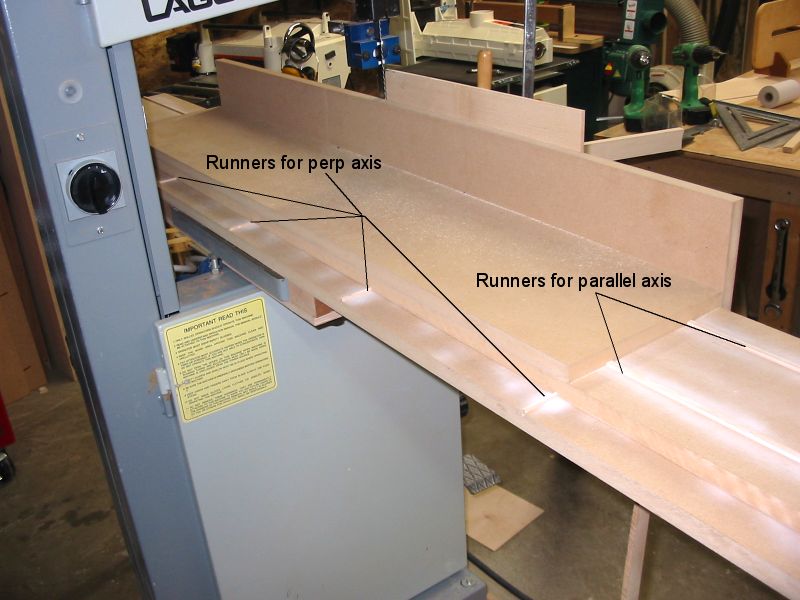

It's basically an X-Y axis table. The axis perpendicular to the blade moves the stock over after each cut while keeping the sled parallel to the blade (adjusted for drift). The sled rides on the parallel axis. The finished version will hold the stock with vacuum, double sided tape for now.

The advantages are that there is no fence for boards to cup against and that the weight seems to reduce vibration while making steady feeding much easier.

My question for those of you who have done a lot of resawwing is, how much waste can you reasonably expect from the kerf AND sanding? I did some cuts in 8" hard maple and the Timberwolf ASS blade I was using took less than .050" and the cut was so clean that I only had to sand about .007" per side to get it totally clean. A total loss a little more than .060". Does it get much better than that? I've only got about 4 hours into this thing so far but tightening it up will be a time sink.

Some photos...